Our Commitment to a Greener Future

As we move into 2025, the field of circuit board design is poised for significant evolution, driven by advancements in technology and changing market needs. The demand for high-performance, compact, and efficient circuit boards is greater than ever, as industries ranging from consumer electronics to medical devices push the boundaries of innovation. Understanding the top trends in circuit board design is crucial for engineers and designers aiming to stay ahead in this competitive landscape.

This year, we anticipate breakout developments in areas such as materials, manufacturing techniques, and design automation, all of which promise to enhance functionality and reduce costs. The integration of artificial intelligence and machine learning into design processes is set to streamline operations, reduce errors, and optimize layout configurations. Furthermore, sustainable practices are becoming increasingly significant, urging designers to consider eco-friendly materials and energy-efficient designs. As we delve into the top trends of 2025, we will explore how these shifts are transforming the circuit board design arena, preparing professionals to adapt and thrive in an ever-evolving technological environment.

As we look ahead to 2025, the landscape of circuit board design is set to undergo significant transformation driven by technological advancements and the increasing demands of diverse applications. One of the most notable trends is the integration of more complex functionalities into smaller form factors. Designers are focusing on creating compact, high-performance circuits that not only save space but also enhance efficiency. This miniaturization process is essential for sectors such as IoT devices, wearables, and smart appliances where size limitations are critical.

Another key trend is the push towards sustainability in circuit board design. Environmental concerns are prompting engineers to explore eco-friendly materials and manufacturing processes. This shift towards green electronics is not just limited to sourcing materials but also extends to promoting energy-efficient designs that reduce the overall carbon footprint of electronic devices. Furthermore, innovations in technology like advanced thermal management solutions are becoming increasingly vital to ensure reliability and longevity in compact circuitry, enabling more sustainable practices in the industry. As we prepare for 2025, being aware of these trends will be crucial for professionals in the field looking to stay competitive and environmentally conscious.

This chart illustrates the top trends in circuit board design that are expected to dominate in 2025. Each trend is represented by its projected adoption percentage, highlighting the growing focus on flexible materials, eco-friendly designs, and artificial intelligence integration in the industry.

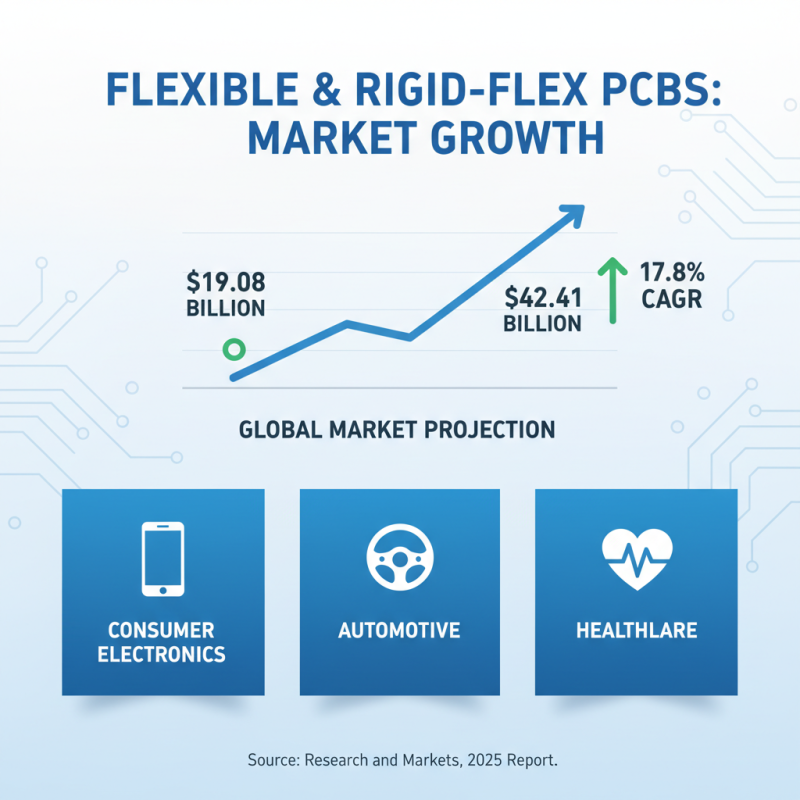

The growing demand for flexible and rigid-flex printed circuit boards (PCBs) is reshaping various industries, particularly in consumer electronics, automotive, and healthcare. According to a recent market analysis by Research and Markets, the global flexible PCB market is projected to grow from $19.08 billion in 2020 to $42.41 billion by 2025, reflecting a compound annual growth rate (CAGR) of 17.8%. This trend underscores the increasing adoption of flexible PCBs, which offer enhanced design flexibility, lightweight characteristics, and superior performance in compact spaces.

In particular, rigid-flex PCBs are gaining traction due to their ability to combine the best features of both flexible and rigid boards. By integrating these two technologies, manufacturers can reduce size and weight, while improving reliability and performance. The IPC Association has reported that the use of rigid-flex designs can lead to a reduction in assembly time by as much as 30%, as they eliminate the need for complex interconnects between multiple board assemblies. This efficiency not only accelerates production but also enables more innovative designs that can meet the demands of next-generation applications, particularly in the microelectronics sector.

As industries look to innovate and enhance the functionality of their products, the rise of flexible and rigid-flex PCB designs is set to play a critical role. These PCBs facilitate advanced technologies like wearable devices, IoT applications, and compact medical equipment, where traditional rigid designs may fall short. Industry experts predict that the integration of these flexible solutions will continue to expand, paving the way for new applications and driving further growth in the PCB market.

The advent of 5G technology is poised to revolutionize the landscape of circuit board design. As data transmission speeds surge and latency decreases, circuit boards must be engineered to accommodate higher frequencies and increased bandwidth. This necessitates the adoption of advanced materials that can handle the thermal and electrical demands posed by 5G, leading to a shift toward substrates like low-loss dielectrics that enhance signal integrity and minimize loss.

Moreover, the miniaturization of devices brought about by 5G requires circuit boards to become increasingly compact and multifaceted. Designers must integrate features such as multilayer structures and embedded components to save space without compromising performance. The heightened density of components calls for innovative manufacturing techniques and stringent quality control measures to ensure reliability under high-speed conditions.

As the pursuit of 5G advancements continues, circuit board design will inevitably evolve to meet these new requirements, paving the way for enhanced connectivity in various applications.

Sustainability has become a crucial consideration in circuit board manufacturing as the industry responds to growing environmental concerns. Research indicates that the global printed circuit board (PCB) market is expected to reach approximately $80 billion by 2025, with a significant portion of this growth driven by the increasing demand for eco-friendly materials. Manufacturers are gravitating towards sustainable options, such as biodegradable substrates and non-toxic soldering materials, to reduce the environmental impact of their products. Reports show that adopting eco-conscious practices not only helps in compliance with regulations but also appeals to a more environmentally aware consumer base.

Tips: When considering materials, look for those that are certified as environmentally friendly, such as FR-4 alternatives made from natural fibers or recyclable plastics. Utilizing lead-free and RoHS-compliant solder can further minimize the ecological footprint of your circuit boards. Additionally, incorporating more efficient manufacturing processes can substantially decrease waste and energy consumption, aligning production with sustainability goals.

Moreover, advancements in technology are enabling better recycling processes for circuit boards, allowing manufacturers to reclaim valuable materials. As per industry analyses, the recovery rate of precious metals and other materials from end-of-life PCBs can reach up to 95%, which not only reduces waste but also mitigates the need for virgin materials. By embracing sustainable materials and recycling technologies, companies can position themselves as leaders in the evolving landscape of eco-friendly electronics.

| Material Type | Eco-Friendliness Score (1-10) | Recyclability (%) | Durability (Years) | Cost per kg (USD) |

|---|---|---|---|---|

| Biodegradable Plastics | 8 | 90 | 5 | 12 |

| Recycled Copper | 9 | 100 | 25 | 10 |

| Natural Fiber Composites | 7 | 75 | 8 | 15 |

| Plant-Based Resins | 8 | 85 | 10 | 18 |

| Eco-friendly Conductive Inks | 9 | 95 | 20 | 22 |

The integration of artificial intelligence (AI) and automation in PCB layout software is transforming the landscape of circuit board design. As designs become increasingly complex, traditional methods of layout are often time-consuming and prone to human error. AI-driven tools are now capable of analyzing design parameters and optimizing layouts in real-time, significantly reducing the design cycle and enhancing accuracy. This shift allows engineers to focus more on innovation and less on repetitive tasks, facilitating the development of advanced circuit boards that meet the demands of modern electronics.

Moreover, automation features in PCB design software simplify collaborative efforts across teams. By streamlining workflow processes and allowing for simultaneous multi-user access, these tools enable design teams to iterate and modify their work dynamically. AI algorithms can assist in identifying potential design flaws before they become problematic, reducing the risk of costly revisions during the production cycle. This synergy between human expertise and machine intelligence not only boosts productivity but also fosters a greater level of creativity in the design process, ensuring that the final products are not only efficient but also innovative and market-ready.