Our Commitment to a Greener Future

As we look towards the future of electronics manufacturing, the landscape of SMT assembly is poised for significant transformation. The year 2025 promises to bring a wave of innovative trends and technologies that will redefine how surface mount technology is integrated into the manufacturing process. This evolution is driven by the increasing demands for miniaturization, enhanced functionality, and the need for greater efficiency in production.

Key trends in SMT assembly are set to emerge, focusing on automation, artificial intelligence, and advanced materials that will not only streamline operations but also enhance the quality and reliability of electronic products. As manufacturers adapt to these changes, the potential for reduced production times and optimized workflows will become more achievable, allowing companies to remain competitive in an ever-evolving market.

In this exploration of the top SMT assembly trends expected to shape the industry by 2025, we will delve into the advancements that are set to revolutionize processes and drive future growth. By embracing these trends, manufacturers will not only improve their operational capabilities but also deliver cutting-edge solutions that meet the demands of a rapidly changing technological landscape.

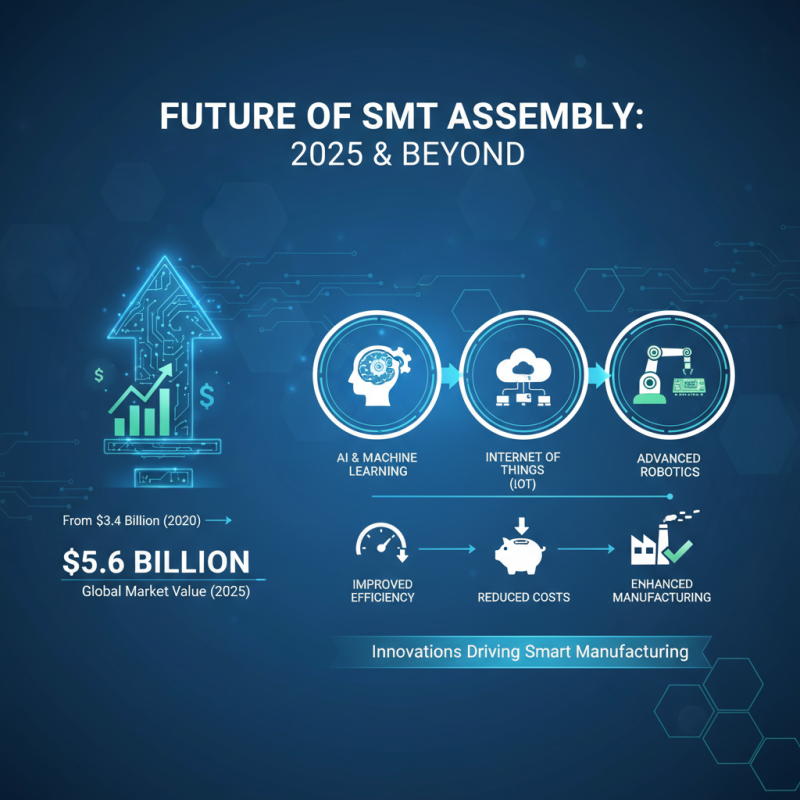

As we approach 2025, the world of surface mount technology (SMT) assembly is set to undergo significant changes driven by emerging technologies. Innovations such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT) are poised to enhance manufacturing processes, improve efficiency, and reduce costs. A recent report by MarketsandMarkets predicts that the global market for advanced SMT assembly technologies will grow from $3.4 billion in 2020 to over $5.6 billion by 2025, highlighting a strong demand for efficient and intelligent manufacturing solutions.

AI-powered automation is expected to streamline production lines, enabling real-time data analysis and predictive maintenance. By utilizing machine learning algorithms, manufacturers can identify inefficiencies and potential failures before they occur, thus minimizing downtime. Additionally, the integration of IoT devices into SMT assembly will facilitate better communication between machines and operators, allowing for instantaneous adjustments and enhanced quality control. According to a forecast by IndustryWeek, manufacturers that adopt smart technologies can expect a productivity boost of up to 30%, showcasing the transformative potential of these innovations in the SMT landscape.

Furthermore, the rise of miniaturization in electronics presents both challenges and opportunities for SMT assembly. As components continue to become smaller and more complex, the demand for precision and accuracy in assembly processes is more critical than ever. Recent insights from IPC, the association connecting electronics industries, emphasize that advanced placement technology and improved soldering techniques will be crucial in addressing these challenges. Those organizations that harness these emerging technologies effectively will not only stay competitive but will also lead the charge in reshaping the future of electronics manufacturing.

The integration of AI and machine learning into the Surface Mount Technology (SMT) process is poised to revolutionize the electronics manufacturing landscape by enhancing efficiency and precision. With smart algorithms that sift through vast amounts of production data, manufacturers can identify inefficiencies in real time, leading to optimized workflows and reduced bottlenecks. This predictive capability allows for proactive maintenance strategies, minimizing downtime and extending the lifecycle of critical equipment.

Furthermore, AI-driven systems facilitate enhanced quality control mechanisms. By employing advanced image recognition and anomaly detection technologies, these systems can automatically inspect solder joints and component placements, ensuring that even the slightest deviations from specifications are addressed before they lead to defective products. The ability to learn from historical data means that these systems not only improve over time but also adapt to new product lines and changing manufacturing conditions, making them invaluable in a rapidly evolving industry. Through such innovations, businesses can achieve higher throughput and lower defect rates, ultimately leading to substantial cost savings and improved competitiveness in the market.

| Trend | Description | Impact on Efficiency | AI/ML Applications |

|---|---|---|---|

| Predictive Maintenance | Utilizing AI to anticipate equipment failures before they occur. | Reduces downtime by over 30%. | Machine Learning algorithms analyze historical data for predictions. |

| Automated Quality Assurance | Implementing AI for real-time defect detection during production. | Increases quality accuracy by 25%. | Computer vision systems powered by AI. |

| Smart Inventory Management | Optimizing material stock levels using AI predictive analytics. | Lowers material costs by 20%. | Machine Learning forecasts demand patterns. |

| Enhanced Process Automation | Integration of robotics to streamline manual assembly tasks. | Improves production speed by 40%. | AI optimizes robotic movements and task scheduling. |

| Data-Driven Decision Making | Using big data analytics to inform strategic manufacturing decisions. | Enhances operational efficiency by 15%. | AI analyzes multiple data streams for insights. |

The electronics manufacturing industry is undergoing a significant transformation as sustainability takes center stage, particularly in Surface Mount Technology (SMT) practices. According to a report by the International Electronics Manufacturing Initiative, around 70% of electronics manufacturers are integrating sustainability measures into their operations, driven by increasing regulatory pressures and consumer demand for greener products. This shift not only helps in reducing carbon footprints but also enhances brand reputation and market competitiveness.

To achieve sustainability in SMT practices, companies are investing in advanced technologies such as automated assembly solutions, which can minimize material waste and energy consumption. Additionally, the adoption of lead-free solder and eco-friendly packaging has gained traction, contributing to a reduced environmental impact. Data indicates that approximately 40% of companies have transitioned to more sustainable materials for their SMT processes, reflecting a growing recognition of the environmental challenges associated with electronics manufacturing.

**Tips:** When aiming for greater sustainability in your SMT practices, consider implementing a comprehensive waste management strategy. This can not only reduce disposal costs but also promote recycling and reuse of materials. Moreover, engaging in regular training programs for employees about sustainable practices can create a culture of environmental responsibility within your organization. Keeping abreast of industry regulations will also ensure compliance and readiness for future sustainability mandates.

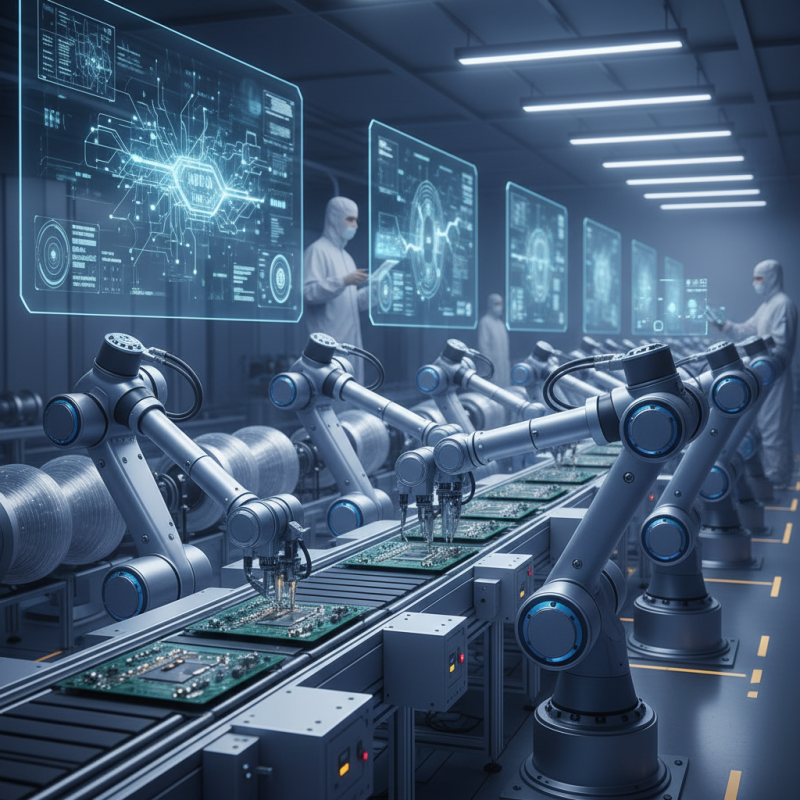

The integration of Industry 4.0 technologies in Surface Mount Technology (SMT) assembly lines is poised to revolutionize the electronics manufacturing landscape by 2025. With the implementation of advanced automation and data analytics, manufacturers are projected to enhance operational efficiency and quality control significantly. According to a report by the International Data Corporation, the global market for Industry 4.0 technologies is expected to reach $3 trillion by 2025, indicating a substantial investment in smart manufacturing processes.

As manufacturers adopt IoT (Internet of Things) devices and machine learning algorithms, real-time monitoring of production lines will become the norm. This shift will enable predictive maintenance, reducing downtime by up to 30%, as noted in a McKinsey analysis. Additionally, data-driven insights will facilitate quicker decision-making, allowing companies to respond promptly to market demands. The rise of smart SMT assembly lines, characterized by interconnected systems and automation, marks a critical trend shaping the future of electronics manufacturing, ultimately leading to lower costs and faster production cycles.

The ongoing shift toward miniaturization and high-density packaging is revolutionizing the landscape of electronics manufacturing. As devices become increasingly compact, manufacturers are challenged to optimize the use of space while ensuring that performance and functionality are not compromised. This trend is driven by the demand for smaller, lighter, and more efficient electronic products, which are essential in various applications, from consumer electronics to advanced medical devices. The integration of components into tighter configurations enables significant advancements such as

enhanced thermal management and reduced signal degradation, contributing to improved overall reliability and efficiency.

High-density packaging also opens avenues for innovative designs and increased functionality within a limited footprint. The adoption of advanced materials and sophisticated manufacturing techniques, such as 3D packaging and embedded components, allows for the creation of intricate circuitry that meets both performance and aesthetic requirements. Furthermore, the increasing complexity of electronic systems necessitates a more strategic approach to design and assembly, prompting manufacturers to invest in cutting-edge technologies and automation. As the trend towards miniaturization and high-density packaging continues to gain momentum, it will undoubtedly shape the future of electronics manufacturing, pushing the boundaries of what is possible in this dynamic industry.