Our Commitment to a Greener Future

The world of PCB fab is constantly evolving. As technology advances, manufacturers seek optimal techniques. Achieving high-quality results requires attention to detail.

Many factors influence PCB fabrication. Materials, processes, and equipment all play crucial roles. Mistakes can lead to significant issues, affecting performance and reliability.

In this article, we’ll explore ten essential PCB fab techniques. Each method aims to boost efficiency and output quality. Using these techniques can help manufacturers adapt and thrive in a competitive landscape. Embracing innovation is vital for success in PCB manufacturing.

Understanding PCB fabrication techniques is crucial for achieving excellent manufacturing results. The process begins with careful design considerations. Engineers must create layouts that accommodate necessary components while maintaining electrical integrity. Each trace and pad must align perfectly. Even minor design flaws can lead to significant issues, like connection failures or signal interference.

After design, various techniques come into play. One common method is photolithography. This involves applying a photosensitive material to the PCB. Then, a light exposure pattern defines circuit paths. Yet, this method has a downside. Imperfections in the mask can result in defects, impacting overall performance.

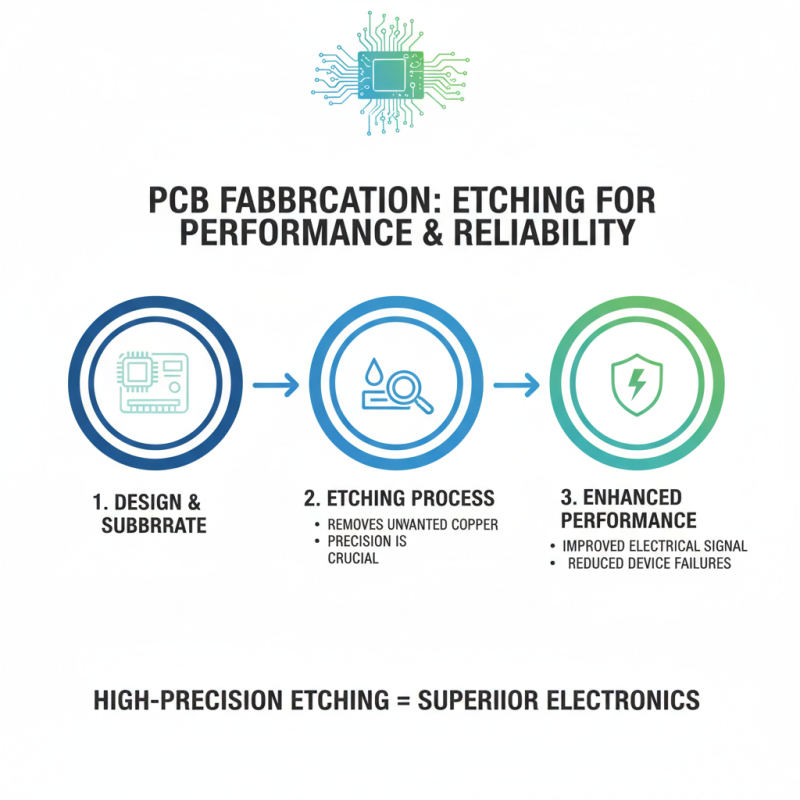

Another technique is etching, where unwanted copper is removed. Precision is key here, as over-etching leads to weak points in the circuit. Additionally, plating is often needed to add more copper layers. Sadly, not all boards will meet durability standards. Continuous improvements can be made, but elements like temperature variations during fabrication can affect outcomes. Understanding these fabrication techniques is essential for making informed decisions.

In PCB manufacturing, several key factors influence quality. The materials used play a crucial role. Substandard substrates can lead to poor performance. A detailed inspection of the materials is essential. Choosing the right combination of copper, resin, and protective coatings can significantly impact durability.

Thermal management is another important consideration. Improper heat distribution can cause failures in electronic devices. Design engineers must account for heat dissipation during the production phase. Inefficient designs may lead to overheating. Additionally, the complexity of the PCB layout can affect manufacturing precision. A cluttered design can complicate the fabrication process.

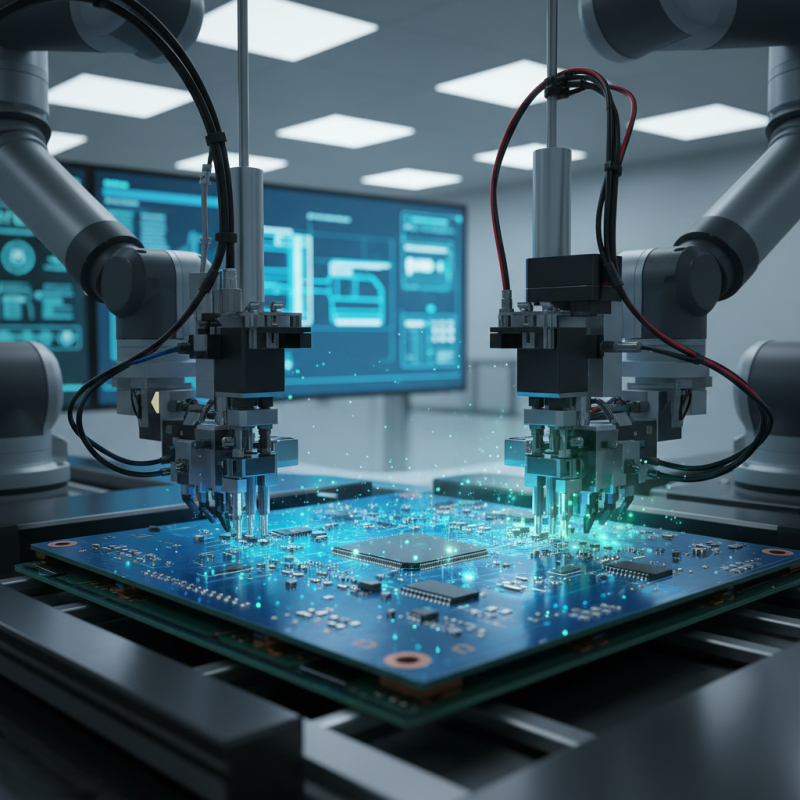

Moreover, the fabrication techniques employed must be carefully evaluated. Many manufacturers rely on outdated processes, which can compromise the final product. Automated machinery often provides better precision than manual labor. Regular calibration of machinery is vital. However, some manufacturers neglect this step, leading to inconsistencies. Implementing rigorous quality control measures can help in identifying flaws early in production.

The printed circuit board (PCB) fabrication process involves various critical techniques essential for high performance. One common method is etching, which removes unwanted copper from the substrate. According to industry reports, etching quality influences both electrical performance and reliability. High-precision etching can reduce failures in electronic devices.

Another vital process is drilling. This step creates holes for vias and mounting components. Data indicates that 60% of PCB defects can be traced back to improper drilling techniques. Many manufacturers struggle here, leading to misalignment issues. A fine-tuned drilling process can minimize these risks, ensuring better connectivity and enhanced durability.

Additionally, surface finishing is crucial. Techniques like HASL and ENIG protect the conductive surfaces. Research shows that about 30% of PCB field failures relate to inadequate surface treatment. Flaws in this stage can lead to corrosion, affecting long-term performance. Reflection on these processes reveals areas for improvement. Implementing stricter quality control in manufacturing could address these common challenges effectively.

In the fast-evolving world of PCB manufacturing, innovations are crucial for enhancing performance. Advanced techniques improve efficiency and quality. New materials offer better thermal management. Improved design software allows for simulation and optimization, ensuring prototypes are more reliable.

Tips: Use simulation tools early in the design phase. This helps identify potential issues before production. Always test different materials to find the best fit.

Manufacturers face challenges with productivity and quality control. Implementing automated processes can streamline production. However, it can lead to dependence on machines. Balancing automation with human oversight is essential for quality assurance.

Tips: Monitor machines closely during production runs. Regular checks can catch unforeseen issues. Don't discount the value of team input; human insights often reveal solutions.

When striving for high-quality PCB fabrication, it is essential to prioritize the design process. An accurate and clear design file can significantly reduce errors during manufacturing. It is crucial to double-check your layout for design rule violations. Overlooking small details can lead to significant issues later. A misaligned trace or misplaced pad may seem minor but can cause circuit failures.

Another critical aspect is material selection. Using subpar materials often results in inconsistencies. The choice of substrate and copper thickness can affect performance. For instance, lighter substrates may provide flexibility but can compromise signal integrity. Finding the right balance is often challenging and requires careful consideration of the project's specific needs.

Communication with the manufacturing team is vital. Discussing tolerances and specifications helps avoid misunderstandings. A common pitfall is assuming everyone is on the same page. Encouraging feedback from the fabricators can improve the overall process. They may identify potential problems that you might have missed. Emphasizing collaboration can lead to better outcomes and prevent costly mistakes.