Our Commitment to a Greener Future

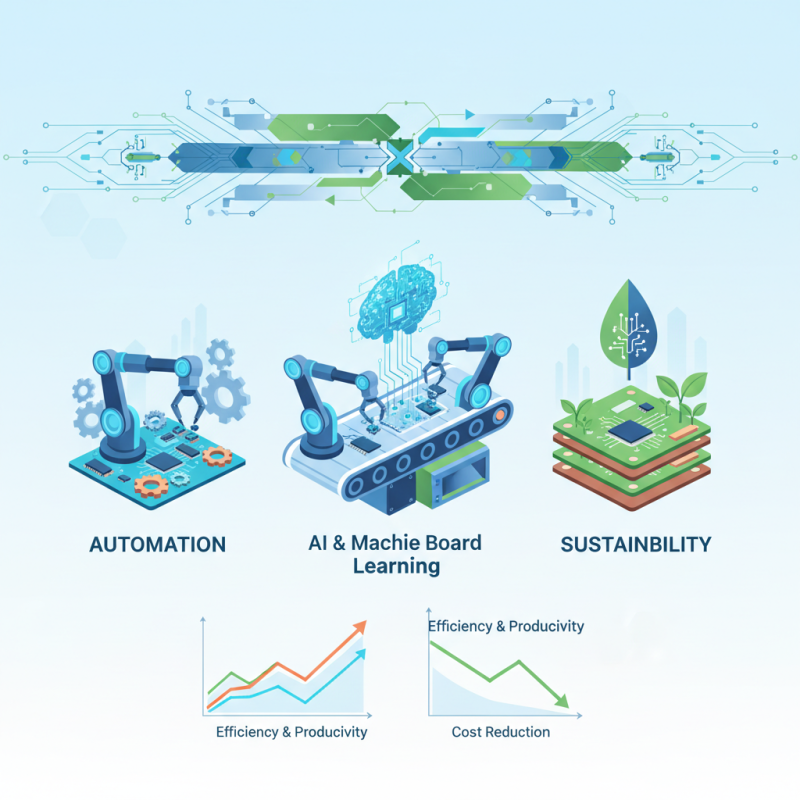

As we approach 2025, the landscape of circuit board assembly is rapidly evolving, influenced by advancements in technology and changing market demands. According to Dr. Emily Chen, a leading expert in electronic manufacturing and circuit board design, "The future of circuit board assembly lies in automation and sustainability, which will redefine efficiency and productivity in our industry." This statement encapsulates the transformative trends that will shape the way circuit boards are assembled in the coming years.

In recent years, we have witnessed significant innovations that impact not only the production processes but also the materials used in circuit board assembly. As environmental concerns gain prominence, companies are increasingly adopting eco-friendly materials and practices. In addition, the integration of artificial intelligence and machine learning into assembly lines is set to enhance accuracy and reduce manufacturing costs, allowing businesses to stay competitive in a fast-paced market.

Staying informed about these trends is crucial for professionals in the circuit board assembly sector. By understanding and adapting to these changes, manufacturers can optimize their operations and meet the growing demands of technology-driven industries. In this article, we will explore the top trends that will define circuit board assembly in 2025 and beyond, paving the way for innovative solutions and sustainable practices.

As we move into 2025, the landscape of circuit board assembly is shifting dramatically, driven by emerging technologies that promise enhanced efficiency and innovation. One of the most significant trends is the rise of automation in the assembly process. Robotics and AI are being integrated into production lines, enabling manufacturers to reduce human error, increase speed, and maintain consistent quality. Automated optical inspection systems are also becoming standard, helping to ensure that assembled boards meet strict quality control standards.

Another trend set to influence circuit board assembly is the increasing adoption of flexible and printed circuit boards. These materials allow for more lightweight and compact designs, essential for the growing demand in consumer electronics, wearables, and IoT devices. As industries push for more complex functionalities in smaller packages, manufacturers are adapting their techniques to accommodate these evolving designs without compromising on performance.

Tip: When considering the transition to flexible PCBs, it’s crucial to collaborate closely with suppliers to understand the unique requirements and potential design challenges.

Additionally, sustainability is emerging as a priority in the circuit board assembly sector. Companies are exploring environmentally friendly materials and processes, such as lead-free solder and recyclable substrates. This shift not only meets the growing consumer demand for eco-friendly products but also aligns with global initiatives aimed at reducing electronic waste.

Tip: To stay ahead in sustainability, regularly evaluate your supply chain for greener alternatives and incorporate eco-conscious practices into your assembly processes.

As circuit board manufacturing navigates the complexities of the modern economy, sustainability practices have emerged as a major force transforming the industry. In 2025, companies are increasingly prioritizing eco-friendly materials and production processes, aiming not just for compliance with regulations but also for long-term environmental stewardship. This shift is leading to innovative approaches such as the use of recyclable substrates and low-impact soldering techniques, which minimize harmful emissions and waste throughout the production cycle.

Moreover, the integration of circular economy principles is becoming prevalent within the circuit board assembly landscape. Manufacturers are rethinking their product life cycles, implementing strategies that emphasize repairability and recyclability. This includes designing products that can be easily disassembled, allowing components to be reused rather than discarded. Additionally, businesses are collaborating with supply chain partners to establish more transparent practices, further supporting sustainability initiatives. This growing emphasis on environmental responsibility is reshaping the expectations of stakeholders, making sustainability not just a trend, but a foundational aspect of circuit board manufacturing in the near future.

As we move towards 2025, the impact of automation on circuit board assembly processes continues to reshape the industry. Automation offers significant advantages, including increased efficiency, reduced human error, and improved production speeds. With advanced technologies such as robotics and artificial intelligence, manufacturers can streamline their assembly processes, allowing for greater flexibility in response to market demands. These innovations not only enhance productivity but also improve the quality of the final products.

Incorporating automation into circuit board assembly requires careful planning and implementation. One tip for successful integration is to start with a pilot program that tests new automated systems on a small scale before full-scale deployment. This approach allows companies to identify any potential challenges and make necessary adjustments without disrupting overall operations. Additionally, investing in employee training on new technologies is essential, as it ensures that the workforce is equipped to manage and maintain automated systems effectively.

To stay competitive in the evolving landscape of circuit board assembly, companies should also consider adopting smart manufacturing practices. This involves using data analytics to monitor production processes in real-time, thereby enabling proactive decision-making. Another tip is to foster a culture of continuous improvement, encouraging employees to share insights and experiences that can lead to innovations in automation and assembly techniques. Such strategies will be crucial for navigating the future of circuit board assembly.

| Trend | Description | Impact of Automation | Expected Outcome by 2025 |

|---|---|---|---|

| Increased Use of AI | AI algorithms enhance quality control and defect detection in assembly lines. | Reduction in human error and faster decision-making processes. | 20% increase in production efficiency. |

| Robotics in Assembly | Greater reliance on robotic arms and automated assemblies for precision tasks. | Enhanced speed and accuracy in assembly tasks. | 15% reduction in assembly time. |

| Smart Manufacturing | Integration of IoT devices for real-time monitoring of manufacturing processes. | Improved operational efficiency through data-driven insights. | 10% reduction in operational costs. |

| Sustainable Practices | Adoption of eco-friendly materials and processes in circuit board manufacturing. | Less waste generation and lower environmental footprint. | 30% reduction in material waste. |

| Advanced Data Analytics | Utilization of big data analytics to predict failures and optimize processes. | Proactive maintenance leading to higher uptime. | 25% increase in overall equipment effectiveness (OEE). |

As the demand for advanced electronic devices continues to surge, the selection of materials for circuit boards is evolving rapidly. In 2025, one of the most significant trends in circuit board assembly will be the shift towards high-performance materials that enhance thermal management and electrical efficiency. Materials such as high-frequency laminates are gaining traction, allowing for improved signal integrity and minimized losses, particularly in applications like 5G technology and IoT devices. These materials help manufacturers meet stringent performance requirements while also promoting miniaturization and lightweight design.

Moreover, the focus on sustainability is leading to the adoption of eco-friendly materials in circuit board manufacturing. Biodegradable substrates and non-toxic solder options are emerging as viable alternatives to traditional materials, aligning with global efforts to reduce electronic waste. The use of recyclable composites not only enhances the environmental credentials of advanced circuit boards but also opens new avenues for innovation in product design. Manufacturers are increasingly prioritizing these sustainable practices, reflecting a broader industry commitment to environmental responsibility while still achieving high performance in their products.

In 2025, the landscape of circuit board production is poised to undergo significant transformations, primarily driven by shifts in supply chain dynamics. As industries recover from disruptions experienced in recent years, manufacturers are emphasizing localization and risk management. The focus is increasingly on establishing robust supply chains that minimize dependencies on distant suppliers. This shift not only enhances resilience but also ensures that production can respond swiftly to regional market demands, ultimately leading to shorter lead times and improved customer satisfaction.

Moreover, technological advancements are reshaping how circuit boards are manufactured and supplied. With the integration of smart technologies, manufacturers can achieve greater transparency throughout their supply chains. Data analytics and real-time monitoring enable firms to predict disruptions and optimize inventory levels effectively. This proactive approach not only mitigates risks but also facilitates more sustainable practices by reducing waste and streamlining logistics. As companies embrace these changes, the circuit board assembly industry will likely see enhanced efficiency and a more dynamic production environment that can adapt to evolving market needs.