Our Commitment to a Greener Future

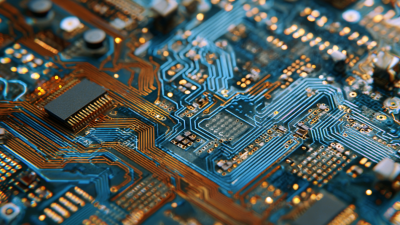

In the ever-evolving world of technology, the demand for high-quality PCB printed circuit boards remains critical. Experts like Dr. Emily Carter, a renowned figure in the PCB industry, emphasize, “Innovation in PCB design is essential for future advancements.” This assertion underscores the importance of selecting the right manufacturers.

As we approach 2026, the landscape of PCB printed circuit board manufacturers is likely to shift significantly. Companies must adapt to new technologies and sustainability demands. It’s not simply about producing boards; it’s about enhancing performance and reducing environmental impact. A few manufacturers excel while others struggle to keep up. This fluctuation poses a challenge for businesses seeking reliable partners.

Choosing the best PCB printed circuit board manufacturers could determine the success of upcoming projects. Companies must evaluate quality, reliability, and innovation. As Dr. Carter suggests, anticipating future needs can foster better partnerships. These considerations ensure that manufacturers not only meet current demands but also drive future progress.

The PCB manufacturing industry in 2026 is influenced by technological advancements. Flexible PCBs gain popularity. They are lightweight and adaptable, suitable for various devices. This trend reflects the growing demand for compact electronics.

Sustainability becomes crucial in manufacturing processes. Eco-friendly materials emerge, responding to environmental concerns. However, the transition to greener methods presents challenges. Companies must invest in new technologies while managing costs.

Despite progress, issues remain. Quality control can suffer with rapid production. As demand increases, maintaining high standards becomes complex. Manufacturers must find a balance between speed and quality. This ongoing struggle could define the industry's future.

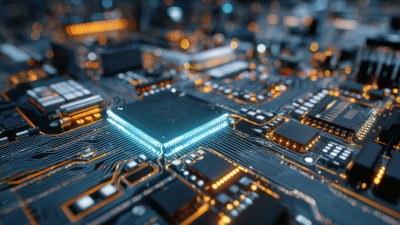

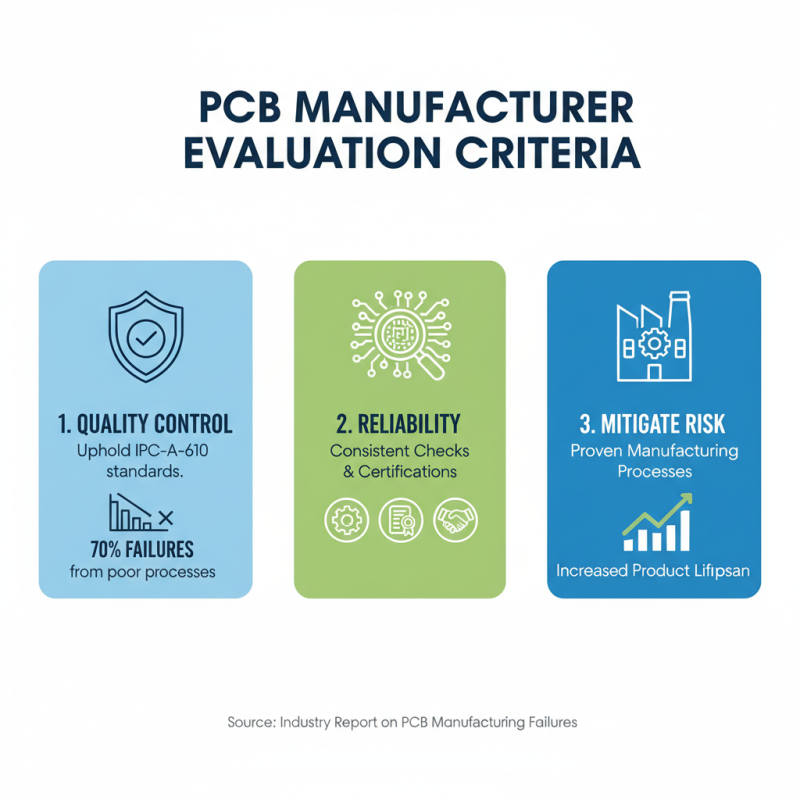

When evaluating PCB manufacturers, several key criteria come into play. Quality control is crucial. A recent industry report indicates that up to 70% of PCB failures are linked to poor manufacturing processes. Manufacturers must adhere to rigorous standards, such as IPC-A-610, to ensure their products meet reliability demands. Consistent quality checks and certifications can help mitigate risks.

Another important factor is production capabilities. The report highlights that manufacturers with the ability to handle high volumes see a 30% increase in customer satisfaction. Speed and efficiency are vital. In today's fast-paced market, the time to market can make or break a product launch. Flexibility in production processes also allows for quick adaptations to design changes.

Lastly, consider customer support and communication. Lack of clear communication can lead to misunderstandings and costly errors. Many manufacturers struggle with this aspect. A study found that companies with strong customer service saw a 40% reduction in project delays. Transparency throughout the process builds trust and ensures alignment. Despite these criteria, many manufacturers still fall short, needing constant reflection and improvement in their operations.

The world of PCB manufacturing has evolved dramatically in the last few years. Each manufacturer specializes in unique aspects of production. Many focus on high-density interconnect designs, while others cater to standard board assemblies. This diversity creates opportunities and challenges.

Some manufacturers excel in rapid prototyping. Their ability to produce small batches quickly is invaluable. This is especially true for startups needing fast turnaround times. Yet, this speed can sometimes compromise quality. Quality control remains crucial, as mistakes can lead to costly reworks.

Others concentrate on sustainable practices. They prioritize eco-friendly materials and processes. However, this often comes with higher production costs. Balancing environmental responsibility and profitability can be challenging. Additionally, not all manufacturers offer the same level of customer support, leading to varied experiences in service quality. It's essential to evaluate each manufacturer carefully to find the right fit.

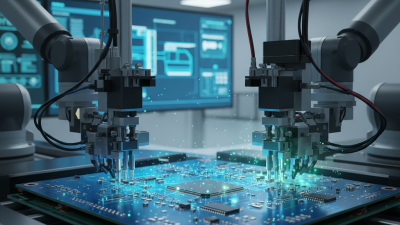

The PCB manufacturing sector is undergoing significant transformation through innovative technologies in 2026. Automation stands out as a key player. Factories are integrating advanced robotics to streamline the assembly process. This boosts efficiency and reduces human error. However, reliance on machines can lead to unexpected malfunctions. Thus, human oversight remains critical.

Another noteworthy trend is the rise of additive manufacturing. This technology allows for quick prototyping and customization of PCBs. It enables manufacturers to create complex designs that were previously difficult to achieve. Yet, this method also brings challenges. Materials used in additive processes can vary in quality, leading to inconsistencies. Ensuring reliability remains a concern.

Moreover, advancements in materials science are influencing PCB production. Flexible and bendable materials enable new applications in electronics. These innovations can enhance product design but may complicate the production process. Manufacturers must adapt quickly to these evolving demands. Balancing innovation with quality control is essential for sustained success in this competitive landscape.

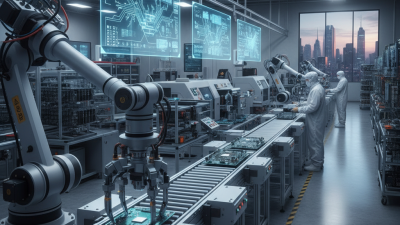

The future for PCB manufacturers in 2026 presents unique challenges and opportunities. The increasing demand for smaller and more complex devices requires innovation. Manufacturers must adapt to rapid technological advancements. Staying competitive means investing in new materials and processes. This can be costly and requires skilled labor.

Sustainability is another pressing issue. Many manufacturers need to reduce waste and improve energy efficiency. Eco-friendly materials are gaining traction, yet sourcing them can be difficult. Moreover, strict regulations pose hurdles for production processes. Companies must balance compliance with innovation to thrive.

Furthermore, the rise of automation can improve efficiency. However, it may also lead to job displacement. Companies must consider workforce training and development. Maintaining a skilled workforce while embracing technology is crucial. Balancing these aspects can create a more resilient manufacturing environment.

| Rank | Manufacturing Capability (sq. ft.) | Lead Time (Days) | Technology Specialization | Key Markets | Sustainability Initiatives |

|---|---|---|---|---|---|

| 1 | 250,000 | 10 | High-Frequency | Telecommunications | Recycling Programs |

| 2 | 200,000 | 15 | Flexible PCB | Consumer Electronics | Solar Energy Adoption |

| 3 | 150,000 | 5 | High-Density Interconnect | Medical Devices | Eco-Friendly Materials |

| 4 | 175,000 | 12 | Multilayer | Automotive | Water Conservation |

| 5 | 300,000 | 20 | Rigid-Flex | Aerospace | Zero Waste Efforts |

| 6 | 225,000 | 9 | Surface-Mount Technology | Industrial Controls | Green Certifications |

| 7 | 180,000 | 11 | High-Voltage | Telematics | Sustainable Manufacturing |

| 8 | 190,000 | 14 | Blind/Buried Vias | Smart Devices | Carbon Footprint Reduction |

| 9 | 160,000 | 8 | Mixed Technology | IoT | Environmental Compliance |

| 10 | 140,000 | 16 | Nano-coatings | Wearable Technology | Resource Efficiency |