Our Commitment to a Greener Future

The selection of an appropriate circuit board is a crucial step in the development of any electronics project. As the backbone of electronic devices, circuit boards facilitate the connectivity and functionality of various components. According to a report by Market Research Future, the global circuit board market is projected to reach $78 billion by 2025, highlighting the increasing demand for efficient and reliable circuit boards in diverse applications. Given this growth, it is imperative for engineers and hobbyists alike to make informed decisions when selecting circuit boards that meet both technical specifications and project requirements.

Expert insights play a vital role in guiding this selection process. Dr. Emily Chen, a recognized authority in circuit board technology, emphasizes the importance of understanding both the material and design of the board. She states, “Choosing the right circuit board can significantly impact the performance, durability, and overall success of your electronics project.” This assertion underscores the significance of evaluating various factors, such as the board's composition, layer count, and manufacturing process, to optimize the design and functionality of the final electronic product. As the circuit board industry continues to evolve, staying informed and making thoughtful selections will be key to achieving innovative and effective electronic designs.

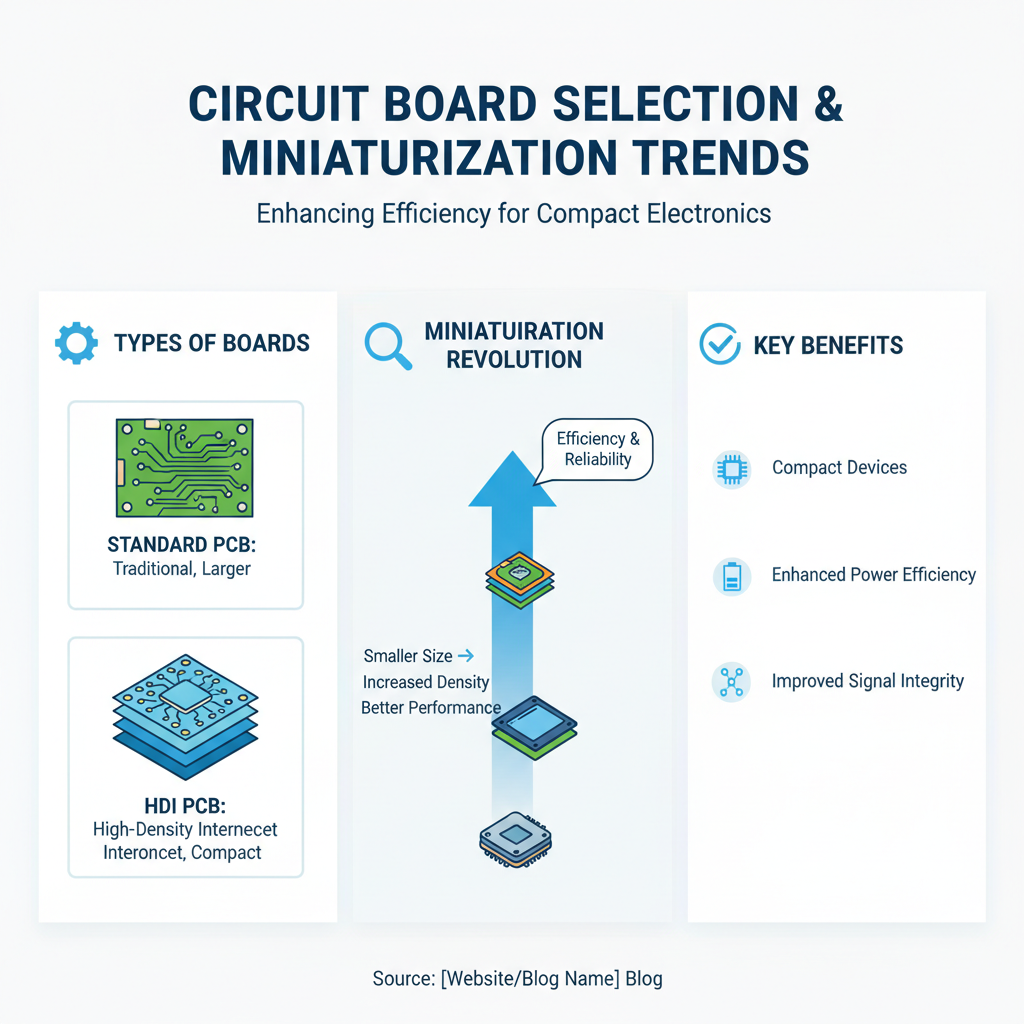

When selecting the best circuit board for your electronics project, it’s essential to understand the different types available in the market. The current trend toward miniaturization is revolutionizing circuit board design, enhancing efficiency and reliability across various industries. By opting for smaller, high-density interconnect (HDI) boards, engineers can achieve better performance and meet the growing demand for compact, lightweight devices.

**Tips:** Consider the specific requirements of your project, such as the operating environment, component density, and thermal management. Choose materials that align with these needs, as they can significantly affect the circuit board's lifespan and performance.

Additionally, the rise of biodegradable substrates signifies a shift toward sustainable practices in electronics manufacturing. With a focus on green technologies, designers should explore these environmentally friendly options for their projects. Evaluating the environmental impact of materials now can lead to safer, more sustainable products in the future.

**Tips:** Look for suppliers who offer eco-friendly materials and conduct thorough research on the performance characteristics of biodegradable options. Prioritizing sustainability will not only benefit the planet but can also appeal to environmentally conscious consumers.

When selecting the best circuit board for an electronics project, it is crucial to assess the specific requirements of the project. The choice of material, complexity, and size of the circuit board can significantly impact the performance and reliability of the final product. For instance, a recent industry report indicates that a well-designed printed circuit board (PCB) can enhance the overall efficiency of electronic devices by up to 20%. This efficiency is particularly vital for projects demanding high reliability and performance, such as in medical devices or aerospace applications.

Additionally, understanding the manufacturing process of PCBs can influence material selection and design. According to a PCB manufacturing plant cost report, costs associated with setup layout and unit operations can vary significantly, impacted by factors like scale and technology used. For example, advanced fabrication techniques may increase upfront costs but can yield better performance and lower failure rates in the long run. Hence, thorough evaluation of project requirements, coupled with a strong understanding of the manufacturing landscape, is essential for effective circuit board selection.

When selecting the best circuit board for your electronics project, three critical factors come into play: size, complexity, and functionality. The size of the circuit board directly influences the compactness of the device and the arrangement of components. According to industry reports, smaller PCB sizes have become increasingly popular, particularly in wearable technology and IoT devices, where every millimeter counts for integration and usability.

Complexity involves not only the intricacy of the circuit design but also the manufacturing processes associated with it. As outlined in a recent study, the complexity of a PCB can impose significant implications on production costs and timelines; for instance, multi-layered boards offer enhanced functionality but can more than double manufacturing costs compared to simpler designs. Understanding the trade-offs between performance and cost is essential for engineers aiming to achieve a balance that meets project requirements.

Functionality is arguably the most pivotal factor; it dictates the components needed and their arrangement on the PCB. Research indicates that approximately 70% of project failures can be traced back to mismatched functionality and design specifications. As technology steadily evolves, ensuring your circuit board aligns with the project's goals is imperative for success in today's competitive electronics landscape.

When selecting a circuit board for your electronics project, understanding material types is crucial as they significantly influence performance. For instance, FR-4, a glass-reinforced epoxy laminate, is the most commonly used material due to its excellent balance between cost, electrical insulation, and thermal durability. According to a report from IPC (Institute of Printed Circuits), FR-4 accounts for approximately 90% of all printed circuit board applications. However, for high-frequency applications, materials like Rogers or Taconic offer superior dielectric properties, reducing signal loss and enhancing overall performance.

Tips: Consider the operating frequency of your project. For high-speed digital designs, materials with a low dielectric constant and loss tangent, like Rogers RT/duroid, are preferable. Also, evaluate thermal management requirements, as certain materials can withstand higher temperatures without degradation.

The choice of substrate material also affects manufacturing processes, such as PCB thickness and layer count. Advanced materials may require specialized fabrication techniques, which can increase lead times and costs. A recent analysis by Research and Markets indicates that the global PCB market is projected to grow steadily, largely driven by advancements in material technologies. This trend emphasizes the importance of selecting the right circuit board material to meet both your project requirements and industry standards.

| Material Type | Dielectric Constant | Thermal Conductivity (W/m·K) | Price per Square Foot | Best Use Case |

|---|---|---|---|---|

| FR-4 | 4.5 | 0.3 | $2.00 | General Purpose |

| CEM-1 | 5.2 | 0.2 | $1.50 | Low-Cost Applications |

| Polyimide | 3.5 | 0.25 | $5.00 | High-Temperature Applications |

| RO4003 | 3.0 | 0.35 | $8.00 | RF/Microwave Applications |

| Alumina | 9.5 | 25.0 | $10.00 | High-Frequency Applications |

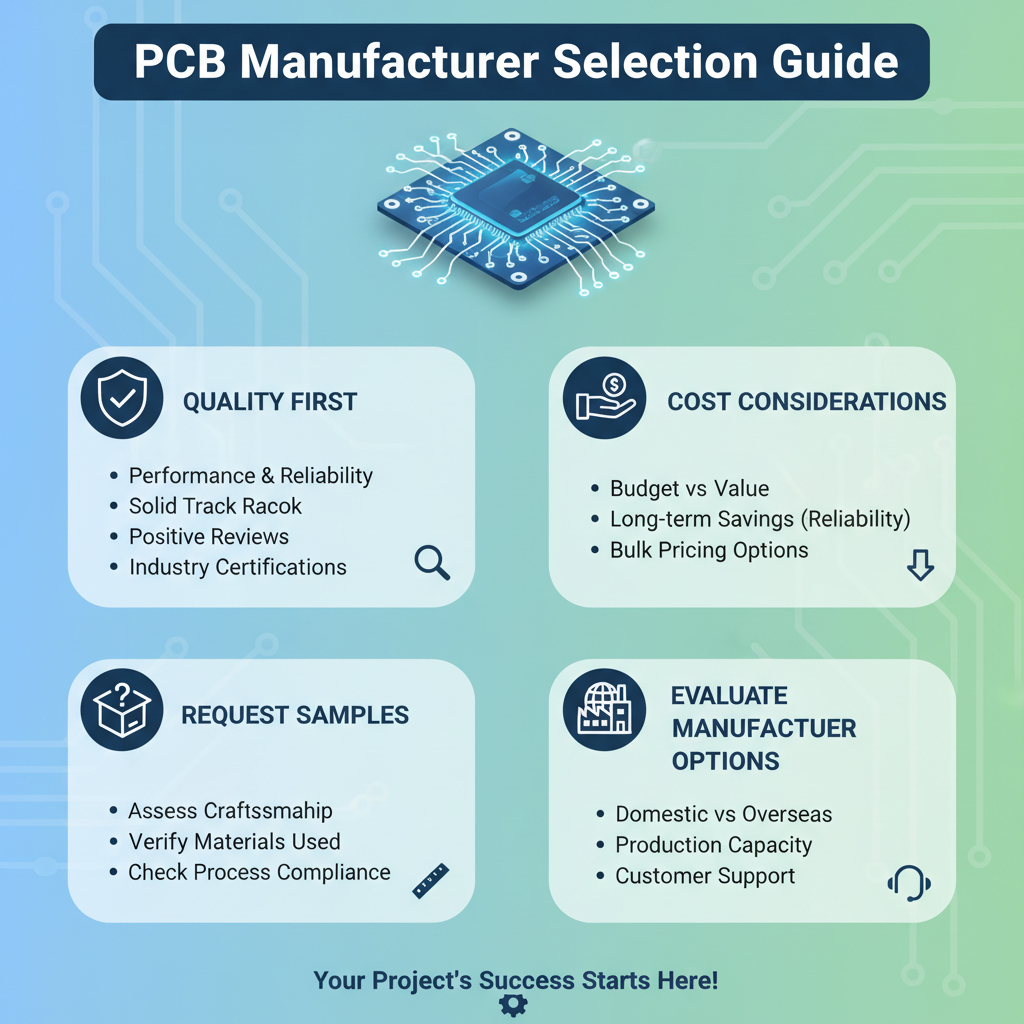

When selecting a circuit board for your electronics project, evaluating manufacturer options becomes crucial, particularly with regard to quality and cost considerations. Quality should be your top priority since the performance and reliability of your electronic device depend heavily on the circuit board’s integrity. Look for manufacturers with a solid track record, positive reviews, and certifications that adhere to industry standards. Request samples to assess the craftsmanship and ensure that the materials and processes used meet your project's specifications.

Cost is also a significant factor when choosing a manufacturer, as it directly affects your project budget. It's essential to weigh the price against the quality of service and products offered. While opting for a cheaper manufacturer might seem appealing, it can lead to compromises in quality that could have long-term repercussions. Consider the total cost of ownership, including potential defects, reworks, and lead times. Engaging with multiple manufacturers for quotes and comparing their offerings can provide insights into the best balance of cost and quality, ensuring your project remains on track and within budget.