Our Commitment to a Greener Future

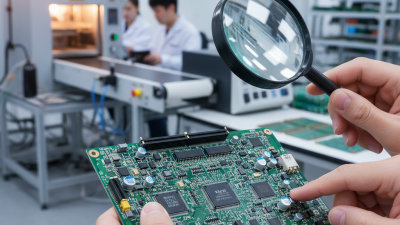

As we look towards 2025, the landscape of electronics manufacturing continues to evolve, creating new challenges and opportunities in the realm of board assembly. Efficient production methods are paramount for manufacturers seeking to maintain a competitive edge in a rapidly changing market. The optimization of board assembly processes is critical, as it directly impacts operational efficiency, cost-effectiveness, and product quality.

In this context, embracing innovative technologies and methodologies will play a pivotal role in enhancing board assembly practices. This includes the integration of automation, real-time data analytics, and advanced material handling systems that streamline workflows and reduce cycle times. By prioritizing the optimization of board assembly, manufacturers can significantly lower operational bottlenecks and improve overall throughput.

Furthermore, fostering a culture of continuous improvement and training within the workforce is essential. As the complexity of electronic components increases, so too does the necessity for skilled labor to navigate these advancements. By focusing on the strategic enhancement of board assembly processes, manufacturers will be well-positioned to thrive in an increasingly competitive atmosphere by 2025 and beyond.

In 2025, the demand for faster and more efficient board assembly processes is expected to rise, driven by the acceleration of digital transformation across industries. According to the latest report from the Institute of Electrical and Electronics Engineers (IEEE), the global electronics assembly market could experience a compound annual growth rate (CAGR) of approximately 6% from 2023 to 2028. This growth underscores the need for streamlined processes to meet consumer expectations for speed without compromising quality.

To optimize board assembly, manufacturers should focus on adopting advanced automation technologies that can significantly reduce production times. Research from the Automation Industries Association (AIA) indicates that implementing robotic systems can increase production efficiency by up to 30%. In addition, utilizing data analytics to monitor and refine assembly workflows can lead to substantial improvements, with studies showing a potential 15% reduction in operational costs when data-driven insights are effectively applied. Overall, integrating these strategies will not only enhance productivity but also ensure that companies remain competitive in a rapidly evolving marketplace in 2025.

| Strategy | Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| Automated Inspection | Utilizing advanced AI to inspect board quality in real-time. | Reduced defects by 30%. | 2025 Q1 |

| Just-In-Time Inventory | Implementing a lean approach to minimize excess inventory. | Improved cash flow and reduced storage costs. | 2025 Q2 |

| Employee Training | Regular training sessions on new technologies and processes. | Increased productivity by 20%. | Ongoing throughout 2025 |

| Process Standardization | Creating uniform procedures for assembly to enhance consistency. | Decreased assembly time by 15%. | 2025 Q3 |

| Advanced Material Utilization | Exploring alternative materials for better performance and lower costs. | Overall cost reduction of 10%. | 2025 Q4 |

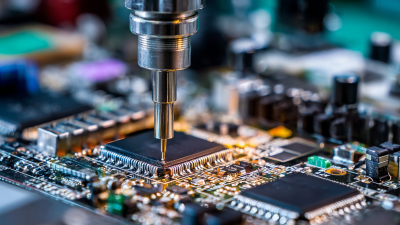

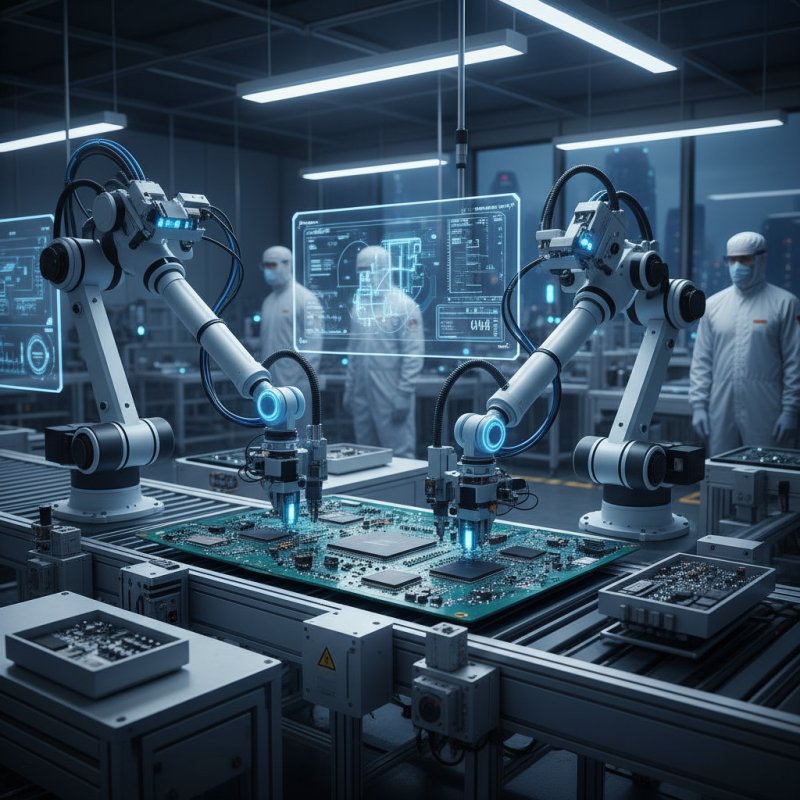

In the rapidly evolving landscape of electronics manufacturing, the integration of automation and robotics into board assembly processes is becoming increasingly crucial for optimizing production efficiency by 2025. According to a report from the International Federation of Robotics, the global industrial robotics market is anticipated to reach $66 billion by 2025, underlining the significant investment in automated solutions. These automated systems enhance precision and speed, reducing human error and leading to higher yield rates in board assembly operations.

The shift towards automation not only streamlines assembly processes but also enables manufacturers to meet the growing demand for complex electronic devices. A study published by the Institute of Electrical and Electronics Engineers reveals that advanced robotics can increase assembly line productivity by up to 40%, allowing companies to scale their operations without compromising on quality. Furthermore, automation technologies, including Artificial Intelligence and machine learning, provide real-time analytics and predictive maintenance, leading to reduced downtime and optimized resource allocation in manufacturing environments. This strategic integration of automation and robotics will ultimately redefine efficiency benchmarks within the industry, paving the way for smarter and more resilient production practices in the years to come.

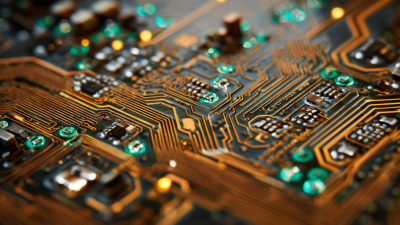

In 2025, the landscape of board assembly is expected to evolve significantly, emphasizing the need for waste reduction and productivity enhancement. A recent report from the Institute of Electrical and Electronics Engineers (IEEE) suggests that optimizing production lines through Lean Manufacturing principles can lead to a 20-30% decrease in waste, translating into substantial cost savings. Implementing Just-In-Time (JIT) inventory practices allows companies to reduce excess inventory that often results in wasted materials. Furthermore, adopting techniques such as Value Stream Mapping helps identify bottlenecks in the assembly process, facilitating targeted improvements.

Advanced automation technologies are also pivotal in maximizing productivity while minimizing waste. According to a study by the International Society of Automation (ISA), integrating robotics and AI-driven systems in assembly lines can boost overall equipment effectiveness (OEE) by up to 50%. These systems enable precise placement and soldering, reducing error rates and scrap levels significantly. Additionally, predictive maintenance powered by IoT sensors ensures that machinery operates at peak efficiency, mitigating downtime and enhancing workflow. Emphasizing these best practices will play a crucial role in shaping sustainable and efficient board assembly processes in the near future.

As we look toward 2025, the optimization of board assembly processes hinges significantly on the integration of advanced materials and technologies. The use of lightweight, durable materials can not only enhance the performance of electronic boards but also streamline production workflows. For instance, materials like flexible substrates and novel polymers offer increased thermal stability and reduced weight, which can lead to more efficient designs and longer-lasting products. By adopting these advanced materials, manufacturers can simplify their assembly processes, reduce waste, and ultimately lower production costs.

In addition, the incorporation of innovative assembly technologies, such as robotics and automation, plays a crucial role in improving efficiency. Automated systems can significantly accelerate the assembly line, allowing for precise placement of components and minimizing human error. Furthermore, technologies such as artificial intelligence and machine learning can optimize production schedules and inventory management, ensuring that resources are allocated effectively. This synergy between advanced materials and cutting-edge technologies sets the stage for a transformative shift in board assembly, positioning manufacturers for success in an increasingly competitive landscape.

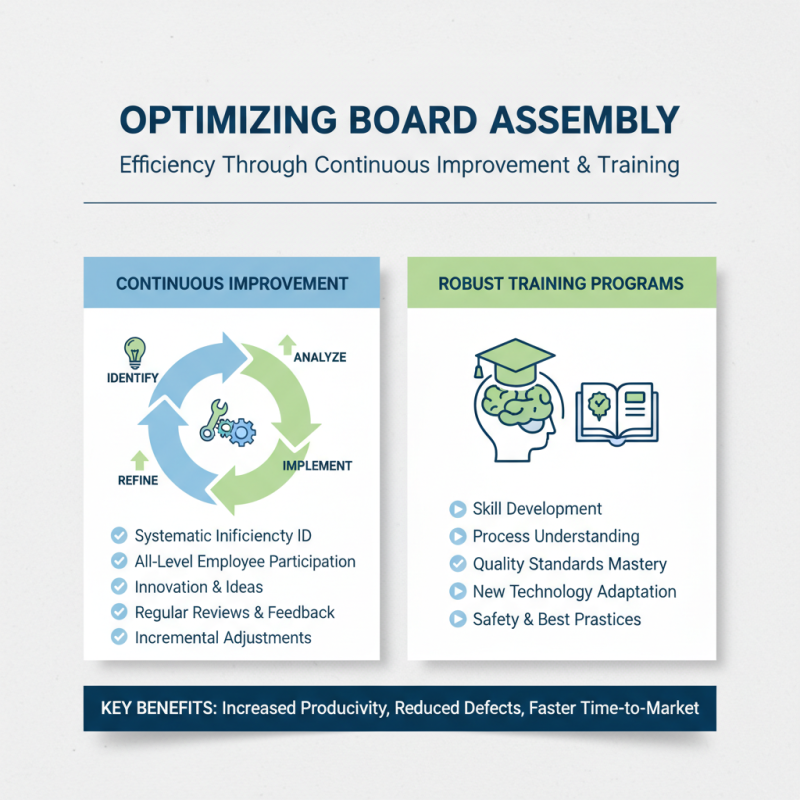

In the pursuit of optimizing board assembly for efficient production, continuous improvement and robust training programs are essential components that can significantly enhance operational efficiency. Implementing a culture of continuous improvement allows organizations to systematically identify and address inefficiencies in their assembly processes. By encouraging employees at all levels to participate in the improvement journey, companies can harness a wealth of ideas and insights that lead to innovative solutions. Regularly scheduled reviews and feedback loops can foster an environment where constant evaluation of workflows results in incremental adjustments that collectively yield significant productivity gains.

Furthermore, investing in comprehensive training programs is crucial for keeping assembly teams skilled and adaptable. As technologies and methodologies evolve, ongoing training ensures that employees are equipped with the latest knowledge and skills necessary to excel in their roles. Structured training programs can cover everything from operational best practices to the use of advanced assembly tools. Incorporating hands-on training, mentorship opportunities, and cross-training across different roles can build a more versatile workforce, ultimately leading to smoother operations and reduced errors on the production line. These training initiatives not only improve individual performance but also enhance team collaboration, creating a cohesive unit focused on achieving optimal outcomes in board assembly.