Our Commitment to a Greener Future

As the backbone of modern electronics, circuit board design (CBD) has become an essential skill in the engineering toolkit, especially for beginners striving to make their mark in the industry. According to a recent report by the International Printed Circuit Association (IPCA), the global printed circuit board market is projected to reach $100 billion by 2025, underscoring the immense potential and growing demand for professionals equipped with CBD skills. As technology continues to advance, the ability to design efficient and reliable circuit boards is becoming increasingly critical.

Expert insights affirm the importance of mastering circuit board design. Dr. Emily Thompson, a leading authority in electronic engineering, states, “Effective circuit board design not only impacts the performance and reliability of electronic devices but also significantly influences production costs and time.” Her perspective highlights the multifaceted nature of CBD, where a solid grasp of both technical and practical aspects can lead to remarkable innovations in product development.

For beginners entering this dynamic field, understanding the foundational concepts and techniques of circuit board design is paramount. This journey can be navigated successfully through a blend of theory and hands-on practice, paving the way for future advancements in technology and engineering.

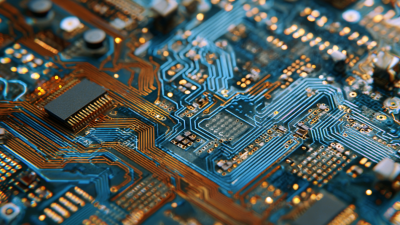

Understanding the basics of circuit board design is crucial for anyone looking to enter the field of electronics. Circuit boards serve as the backbone of electronic devices, providing a platform where electronic components can be connected and function together harmoniously. At its core, a circuit board consists of a non-conductive substrate layered with pathways made from conductive materials, known as traces. These traces connect various components like resistors, capacitors, and integrated circuits, allowing them to communicate and operate as intended.

For beginners, grasping fundamental concepts such as schematic diagrams, the role of each component, and how to lay out these components on a circuit board is essential. A schematic diagram is essentially a roadmap of the electrical design, showing the connections and relationships between components. Learning to read and create these diagrams helps in visualizing the circuit’s functionality before actual board layout begins. Additionally, understanding design rules concerning trace width, spacing, and component placement can greatly affect the performance and reliability of the final product. Engaging with simulation software can also provide insights into how the circuit will behave, allowing for adjustments and optimizations before committing to the physical design. By focusing on these foundational aspects, beginners can build the confidence and skills necessary to master circuit board design.

| Tip/Technique | Description | Importance |

|---|---|---|

| Start with a Schematic | Create a detailed schematic diagram to visualize the circuit before layout. | High |

| Choose the Right Software | Select PCB design software that fits your experience level and project needs. | Medium |

| Understand PCB Layering | Learn how to effectively use multiple layers to optimize design and minimize interference. | High |

| Follow Design Rules | Adhere to design rules related to trace width, clearance, and spacing to ensure functionality. | Critical |

| Prototype and Test | Build prototypes and run tests to validate the design before final production. | Very High |

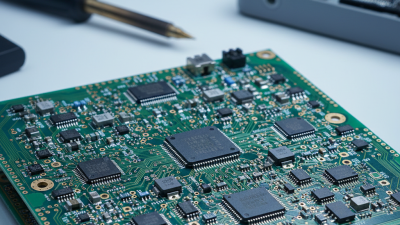

When diving into circuit board design, choosing the right tools and software is crucial for beginners. A robust electronic design automation (EDA) tool can make a significant difference in your workflow. Look for software that offers features like schematic capture, layout design, and simulation capabilities. An ideal EDA tool should enable you to visualize your circuit in both 2D and 3D, ensuring you can identify potential design issues early in the process.

In addition to software, having the appropriate hardware tools is essential. A digital multimeter allows you to measure voltage, current, and resistance, aiding in troubleshooting and validation of your designs. Similarly, an oscilloscope is invaluable for observing signal waveforms and ensuring your circuits operate as intended. For beginners, investing in a basic prototyping board can facilitate hands-on experimentation, allowing you to test your designs in real-world conditions before committing to a final layout. Together, these tools create a solid foundation for mastering circuit board design.

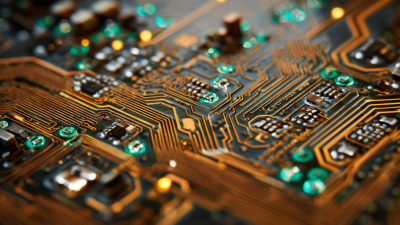

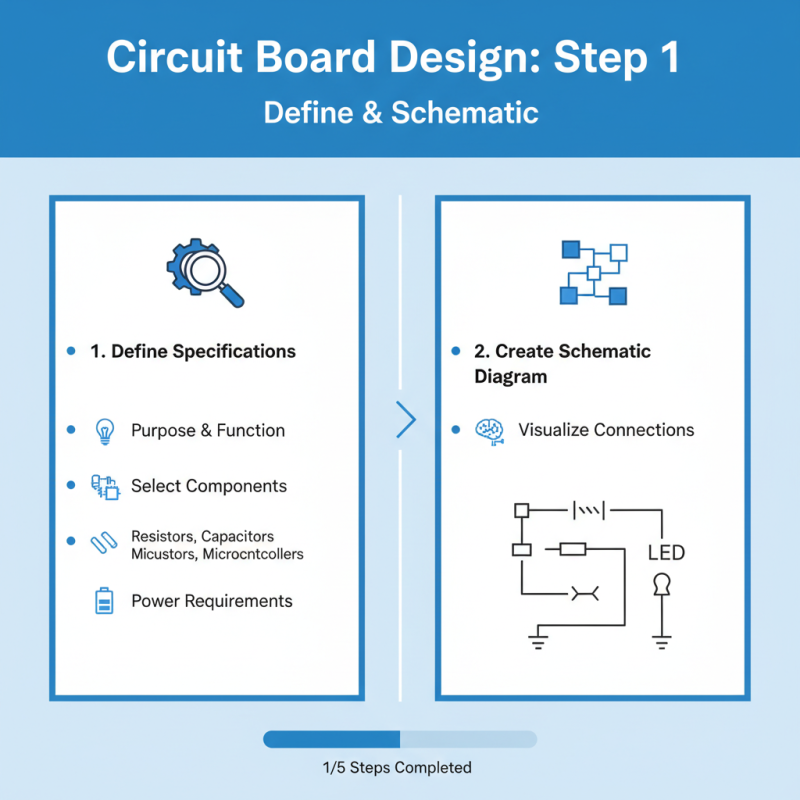

Designing a circuit board can seem daunting for beginners, but breaking it down into a step-by-step process can make it much more manageable. The first step is to define the specifications of your circuit, including the purpose it will serve and the components required. This involves selecting the right parts, such as resistors, capacitors, and microcontrollers, that will meet your project’s needs. Creating a schematic diagram to visualize the connections between these components is essential, as it serves as a roadmap for the layout of your circuit board.

Once you have a clear schematic, the next phase is to design the physical layout of the circuit board. Using software tools, you can arrange the components on the board while ensuring proper spacing and orientation. It is crucial to adhere to best practices such as minimizing the length of traces, optimizing for signal integrity, and considering thermal management. After finalizing the layout, reviewing and checking for design rule violations helps prevent potential issues during manufacturing. By meticulously following these steps, beginners can effectively design functional and reliable circuit boards ready for prototyping and testing.

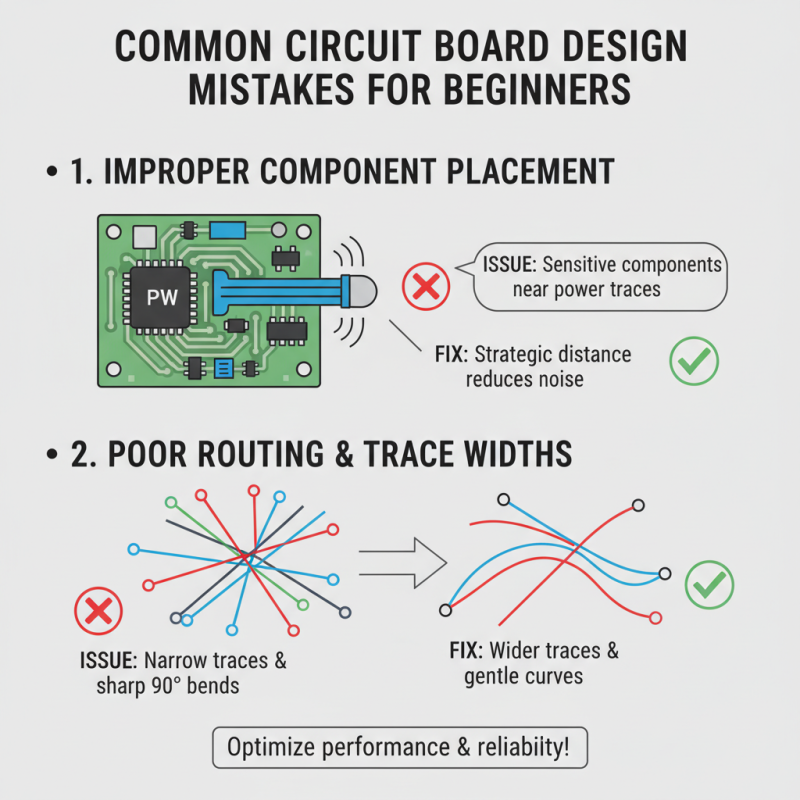

When diving into circuit board design, beginners often make common mistakes that can impact the performance and reliability of their projects. One prevalent issue is improper component placement. Each component should be strategically placed to minimize signal noise and optimize connection routes. Beginners may overlook the importance of keeping sensitive components away from power traces, which can lead to interference and erratic behavior in circuits.

Another frequent mistake is neglecting to account for the board's thermal management. Failing to consider heat dissipation can lead to overheating, which not only affects the performance of the components but can also result in permanent damage. Ensuring adequate spacing and incorporating heat sinks or thermal pads when necessary can safeguard the functionality of the circuit. Additionally, beginners often underestimate the significance of comprehensive testing before finalizing a design. It is crucial to simulate and prototype the circuit board to identify potential issues early on, preventing costly errors down the line.

Testing and troubleshooting circuit boards is a critical skill for any electronics designer, particularly for beginners. According to a 2022 survey conducted by the Institute of Electrical and Electronics Engineers (IEEE), nearly 40% of new engineers identified testing and troubleshooting as their greatest challenge in circuit board design. To effectively address this challenge, it’s crucial to adopt a systematic approach to diagnostics. Begin with visual inspections to identify obvious issues such as loose connections or burnt components. According to PCB Design Magazine, these visual checks alone can resolve up to 30% of the problems encountered in prototypes.

Once the initial inspection is conducted, employing the right tools is essential for a thorough assessment. Multimeters, oscilloscopes, and logic analyzers are fundamental in pinpointing failures. The 2021 PCB Testing Report revealed that approximately 45% of failures can be diagnosed through electrical testing methods, highlighting the importance of using these essential instruments. Furthermore, simulation software can provide valuable insights before actual testing, predicting potential failure points and allowing designers to optimize their layouts. Fostering a proactive attitude towards testing not only enhances design reliability but also significantly reduces time-to-market, an essential factor in today’s competitive electronics landscape.