Our Commitment to a Greener Future

In the fast-evolving landscape of electronics manufacturing, the significance of SMT assembly cannot be overstated. As the industry continues to demand higher efficiency and precision, experts like Dr. Emily Chen emphasize the critical role that SMT assembly plays in enhancing production capabilities. She once noted, "SMT assembly is not just a method; it is the backbone of modern electronics production, enabling innovation and speed to market." This sentiment captures the essence of why businesses must prioritize SMT assembly in their manufacturing processes.

The transition to Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled. Unlike traditional through-hole methods, SMT allows for a more compact design and faster assembly times, essential attributes in a market driven by rapid technological advancements. As manufacturers face increasing pressure to produce smaller, lighter, and more powerful devices, the adoption of SMT assembly becomes paramount.

As we delve into the critical aspects of SMT assembly, it is evident that this technique is not merely a trend but a fundamental necessity for achieving success in modern electronics manufacturing. Through understanding its benefits and applications, manufacturers can stay ahead of the competition and drive innovation in their product offerings.

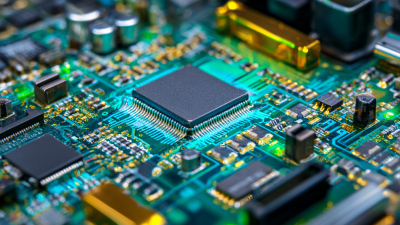

Surface Mount Technology (SMT) assembly plays a pivotal role in the success of modern electronics manufacturing. As electronic devices become more compact and complex, the demand for high-density circuit boards has surged. SMT allows manufacturers to mount components directly onto the surface of PCB (printed circuit board), optimizing space and enabling the integration of smaller, yet more powerful components. This technology caters to the requirements of today's miniaturized electronics, such as smartphones, tablets, and wearable devices, ensuring that they remain efficient and capable of handling advanced functionalities.

The importance of SMT assembly extends beyond just physical space optimization. This method enhances the reliability and durability of electronic assemblies. By minimizing the length of connections between components, SMT reduces signal loss and improves performance. Furthermore, the automated nature of SMT assembly facilitates higher production speeds and consistent quality, significantly lowering the chances of human error that can occur in traditional through-hole assembly processes. As a result, manufacturers can achieve quicker turnaround times and meet the ever-growing consumer demand without compromising on quality or performance.

Surface Mount Technology (SMT) assembly is a critical process in modern electronics manufacturing, characterized by its efficiency and precision. The fundamental components of the SMT assembly process begin with the design phase, where electronic schematics are translated into layout designs to optimize space and functionality on printed circuit boards (PCBs). This design must take into consideration the placement of surface mount devices (SMDs), which are an integral part of the final product's performance.

Once the design is established, the SMT process progresses to the solder paste application stage, where a solder paste stencil is used to apply solder paste onto the PCB pads. Following this, components are accurately placed on the board using high-speed pick-and-place machines. These machines enhance productivity by rapidly positioning thousands of components per hour with remarkable precision. After placement, the boards undergo reflow soldering, a critical step where the solder paste is melted to securely attach SMDs to the PCB, ensuring strong electrical connections. Each of these stages highlights the importance of meticulous execution and quality control, which are essential for the reliability and functionality of modern electronic devices.

Surface Mount Technology (SMT) assembly has become a cornerstone of modern electronics manufacturing, offering numerous benefits that drive efficiency and innovation. One of the primary advantages of SMT assembly is its ability to facilitate miniaturization. According to a report from TechNavio, the global SMT market is projected to grow at a CAGR of over 5% from 2021 to 2026, demonstrating the increasing reliance on this technology. SMT components are smaller and lighter than their through-hole counterparts, allowing manufacturers to produce compact devices without sacrificing performance. This smaller footprint is particularly advantageous in sectors such as consumer electronics and medical devices, where space is often at a premium.

Another significant benefit of SMT assembly is its increased production speed and cost-effectiveness. By employing automated placement machines, manufacturers can achieve higher throughput rates, significantly reducing assembly times. A study by IPC indicated that integrating SMT in assembly lines can lead to a reduction in labor costs by up to 30% while also minimizing material waste. This not only enhances overall productivity but also helps in sustaining environmentally friendly practices by optimizing resource usage.

Tips: When considering SMT assembly for your production needs, it’s essential to ensure your design is optimized for the technology. Use a mix of surface mount and through-hole components wisely, as placing too many surface mount types can complicate the design unnecessarily. Additionally, regularly reviewing quality control processes can help catch potential issues early in the assembly phase, thus ensuring a smoother production cycle.

| Benefit | Description | Impact on Manufacturing | Industry Application |

|---|---|---|---|

| Space Savings | SMT components are smaller, allowing for denser circuit designs. | Increased board space utilization and reduced product size. | Consumer Electronics, Telecommunications |

| Lower Production Costs | Reduction in material costs and labor due to automation. | Decreased overall cost per unit in high-volume production. | Automotive, Healthcare Devices |

| Improved Electrical Performance | Shorter interconnections reduce inductance and resistance. | Enhanced signal integrity and faster operation speeds. | Computing, Communication Systems |

| Better Thermal Performance | Thermal pathways are optimized with SMT layout design. | Improved heat dissipation leads to reliable operation. | Power Electronics, LED Lighting |

| Flexibility in Design | SMT technology allows for innovative circuit designs. | Greater product differentiation and quicker design cycles. | Consumer Goods, IoT Devices |

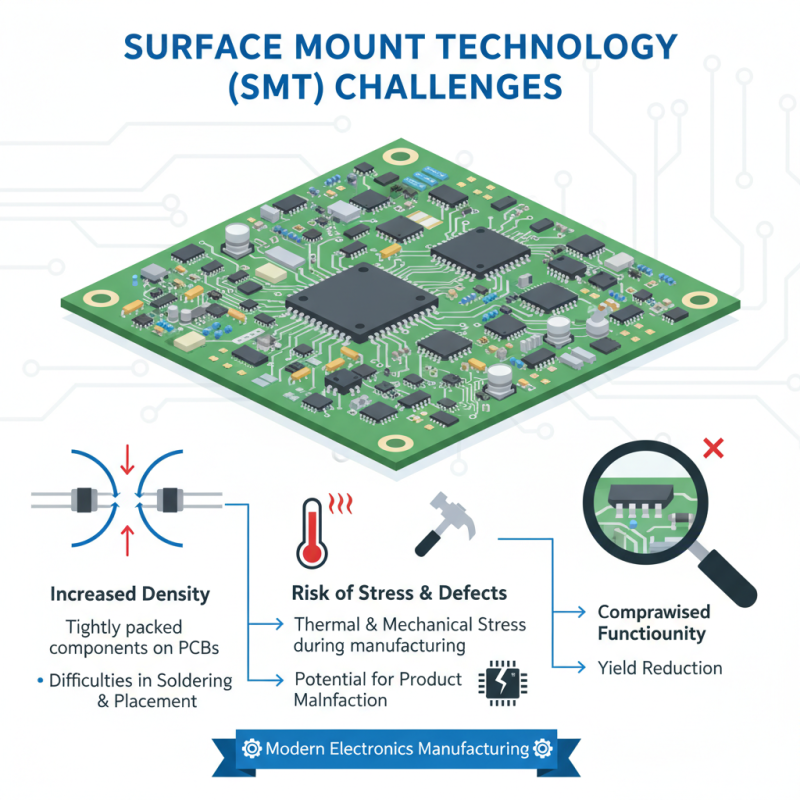

Surface Mount Technology (SMT) assembly has become a cornerstone of modern electronics manufacturing due to its ability to meet the demands for smaller, more complex devices. However, this technology is not without its challenges. One significant issue is the increased density of components on printed circuit boards (PCBs), which can lead to difficulties in soldering and component placement. As components are packed tightly together, there is a heightened risk of thermal and mechanical stress during the manufacturing process, potentially resulting in defects that could compromise the functionality of the final product.

To address these challenges, manufacturers are adopting advanced automation systems and high-precision placement machines that improve alignment and soldering accuracy. Implementing a robust quality control process, including real-time monitoring and feedback systems, can significantly enhance production reliability. Furthermore, embracing the latest advancements in solder materials can help mitigate thermal stress and improve the overall durability of the assemblies. By investing in these solutions, manufacturers can overcome the complexities of SMT assembly, ensuring efficient production and enhanced performance of modern electronic devices.

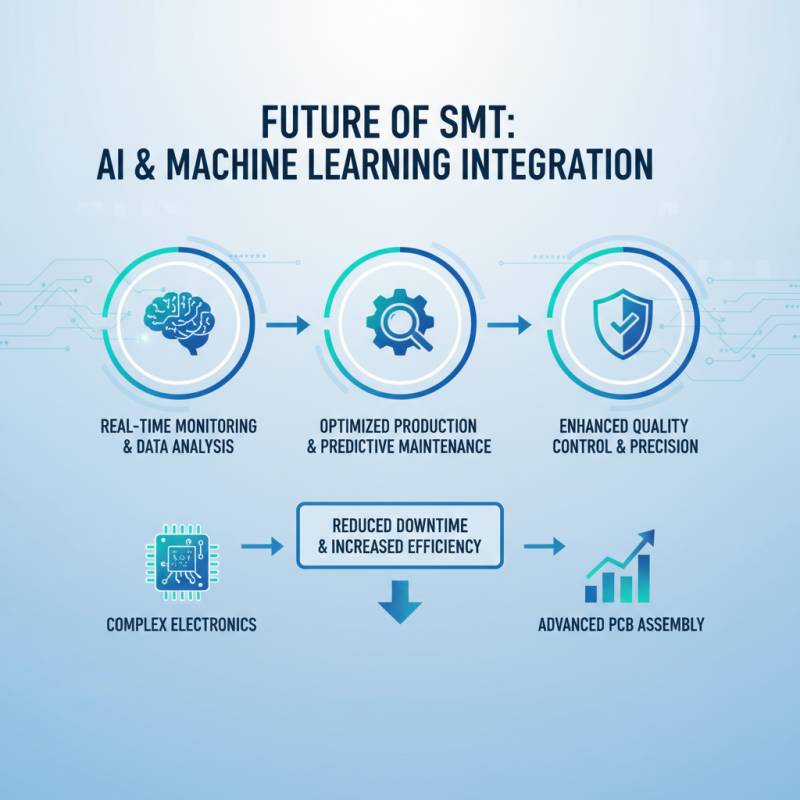

The future of Surface-Mount Technology (SMT) holds promising advancements that will further enhance the efficiency and capabilities of electronics manufacturing. One of the most significant trends is the integration of artificial intelligence and machine learning into the SMT assembly process. These technologies enable real-time monitoring and data analysis, allowing manufacturers to predict maintenance needs, optimize production schedules, and enhance quality control. By leveraging AI, companies can reduce downtime and improve the precision of PCB assembly, addressing the increasing complexity of modern electronics.

Another trend is the move towards miniaturization and 3D packaging, which reflect the industry's demand for smaller, more powerful devices. Innovations in SMT equipment are making it possible to place components more densely on circuit boards without compromising performance. This not only allows for more compact designs but also aligns with sustainability goals by reducing material waste. The emergence of advanced soldering techniques and materials, combined with improved automation, is set to revolutionize assembly processes, enabling manufacturers to meet consumer expectations for high-performance electronics in increasingly smaller form factors.