Our Commitment to a Greener Future

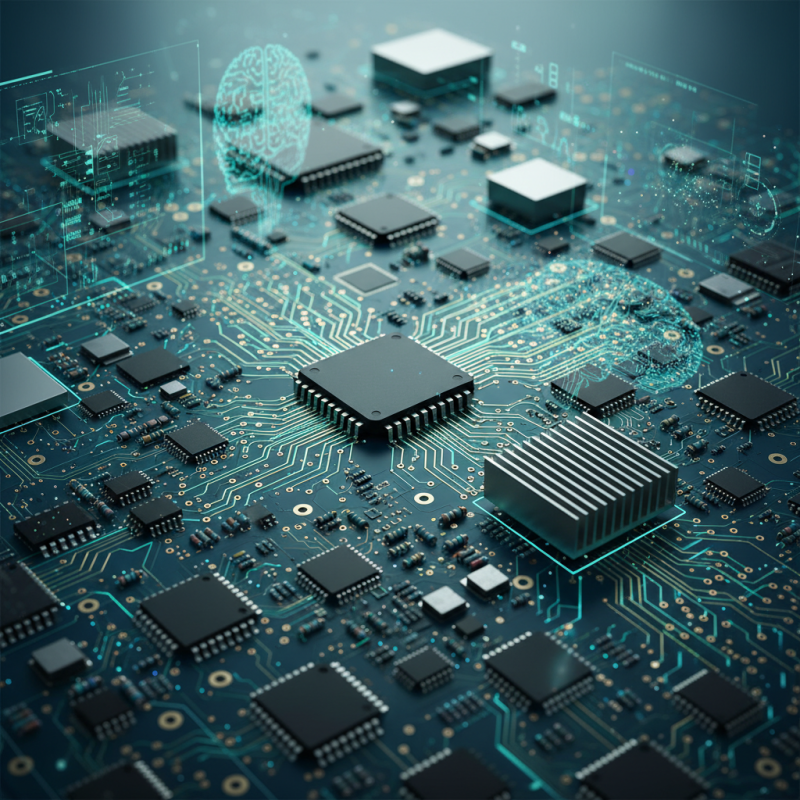

In the realm of electronics, the circuit board serves as the foundation upon which virtually all modern devices are built. Dr. Emily Chen, a leading expert in electrical engineering, aptly stated, "A circuit board is not just a component; it is the brain that orchestrates the behavior of electronic systems." Understanding what a circuit board is—and the various types and functions it encompasses—is crucial for anyone seeking to delve into the intricate world of electronics.

Circuit boards are essential for connecting different components, allowing for seamless communication and functioning within devices. They can be found in a multitude of applications, from smartphones to home appliances, each tailored to meet specific operational requirements. The wide variety of circuit boards available today, including Printed Circuit Boards (PCBs), Flexible Circuit Boards, and Rigid-Flex Boards, serve diverse needs across industries. In this exploration, we aim to demystify these components, highlighting their significance and the roles they play in our everyday technology, ultimately emphasizing why understanding circuit boards is essential in the contemporary electronic landscape.

A circuit board, often referred to as a printed circuit board (PCB), is an essential component in modern electronics, serving as the foundation for connecting various electronic components. At its core, a circuit board is made of a non-conductive material, typically fiberglass, with conductive pathways etched onto its surface. These pathways facilitate the flow of electricity and signals between different components, such as resistors, capacitors, and microchips, enabling the functionality of electronic devices.

The design of a circuit board can vary significantly based on its intended application. There are single-sided boards, which have components on one side and copper traces on the other, and more complex multi-layer boards that stack several layers to accommodate a higher density of components. This versatility allows circuit boards to be utilized in a myriad of devices, from simple home appliances to sophisticated aerospace equipment. Understanding the basics of circuit boards opens up insights into the intricate workings of electronics that power our everyday lives.

A circuit board, often referred to as a printed circuit board (PCB), is a vital component in electronic devices, serving as a foundation where various electronic components are mounted and interconnected. The basic components of a circuit board include resistors, capacitors, diodes, and integrated circuits. Each of these elements plays a critical role in the functionality of the device. Resistors limit the flow of electric current, capacitors store and release energy, diodes allow current to flow in one direction, and integrated circuits can perform complex computations and control various functions.

When designing or assembling a circuit board, it’s essential to consider the layout and placement of these components for optimal performance. Proper spacing, orientation, and soldering techniques can prevent short circuits and enhance signal integrity.

Tips: Always double-check your connections and component orientation before powering up your circuit board. Using a multimeter can help identify any potential issues during the assembly process. Additionally, keeping your work area organized will help you avoid losing small components and maintain an efficient workflow.

Circuit boards, commonly known as printed circuit boards (PCBs), play a critical role in the functionality of modern electronic devices. The main types of circuit boards include single-sided, double-sided, and multi-layer boards, each serving specific applications and offering unique advantages. According to a report by Transparency Market Research, the global PCB market was valued at approximately $63 billion in 2020 and is expected to grow significantly in the coming years, driven by the increasing demand for consumer electronics and technological advancements.

Single-sided boards, with components mounted only on one side, are widely used in simple electronic devices due to their cost-effectiveness and ease of manufacturing. Double-sided boards allow for more complex designs, accommodating components on both sides, which is ideal for applications requiring more circuitry in limited space. Multi-layer boards, consisting of multiple layers of conductive materials separated by insulating substrates, provide advanced electrical performance and are essential in high-frequency applications. Research indicates that multi-layer boards represent a substantial portion of the PCB market and are critical for industries such as telecommunications, automotive, and aerospace, where reliability and performance are paramount.

The versatility of these circuit boards enables them to cater to various industries, from medical devices to consumer gadgets. As technology continues to evolve, the demand for innovative circuitry solutions will only increase, prompting ongoing advancements in PCB design and manufacturing processes. This growth underscores the vital role circuit boards play in shaping the electronic landscape and driving progress across multiple sectors.

Circuit boards play a crucial role in modern electronic devices, serving as the backbone that interconnects various components and facilitates their communication. These boards, composed of insulating substrates with conductive pathways, provide electrical connectivity and mechanical support for components such as semiconductors, resistors, and capacitors. According to a report by Research and Markets, the global printed circuit board (PCB) market is expected to reach $82 billion by 2025, highlighting the increasing demand for these essential components in various applications, from consumer electronics to automotive systems.

The functions of circuit boards extend beyond simple connectivity. They allow for the integration of multiple functionalities into a compact space, enabling complex electronic systems to operate efficiently. Notably, circuit boards contribute to signal integrity and electromagnetic compatibility, ensuring that devices function reliably without interference. A study by IPC outlines that the implementation of advanced circuit board designs can reduce energy consumption by up to 30%, reflecting their significance in enhancing the performance and sustainability of electronic devices. As technology continues to evolve, circuit boards will remain at the forefront, adapting to meet the needs of innovative applications in the rapidly changing electronic landscape.

The manufacturing process of circuit boards is a critical aspect of modern electronics and involves several intricate steps that ensure quality and performance. Typically, the creation of a printed circuit board (PCB) begins with the design, where engineers use sophisticated software to define the layout and electrical connections. This design phase accounts for approximately 30% of the overall cost and effort in PCB production, as it determines the functionality and efficiency of the final product.

Following the design, the manufacturing process involves various processes such as etching, layering, and soldering. Data from industry reports indicate that global PCB production reached an estimated $60 billion in 2022, with a projected growth rate of 5.6% annually through 2025. This growth is driven by advancements in technology and an increasing demand for smaller, more complex electronic devices. Additionally, manufacturers are adopting more automated practices to improve speed and efficiency in production, allowing for faster turnaround times and reduced labor costs.

Tips: When considering PCB manufacturing, it’s essential to collaborate closely with your design team to ensure that the layout is optimized for the chosen materials and processes. Furthermore, evaluate the supplier's capabilities to handle the specific types of circuit boards you require, as not all manufacturers specialize in the same materials or technologies. Taking these steps can significantly enhance product quality and reduce time-to-market.

| Type of Circuit Board | Function | Common Applications | Manufacturing Process |

|---|---|---|---|

| Single-Sided PCB | Basic circuitry on one side | Consumer electronics, LED lighting | Etching, drilling, soldering |

| Double-Sided PCB | Components on both sides | Audio devices, power supplies | Layer stacking, vias, soldering |

| Multi-Layer PCB | Increase density of design | Computers, smartphones, medical equipment | Lamination, plating, etching |

| Flexible PCB | Bendable for compact designs | Wearable tech, mobile devices | Film application, lamination |

| Rigid-Flex PCB | Combines rigid and flexible sections | Aerospace, medical devices | Layering, multilayer assembly |