Our Commitment to a Greener Future

The field of circuit board manufacturing is poised for significant growth in 2025, driven by the rapid advancement of technology and the increasing demand for electronic devices. According to recent reports by industry analysts, the global printed circuit board (PCB) market is anticipated to reach a staggering USD 82 billion by 2025, primarily fueled by the burgeoning sectors of consumer electronics, automotive technology, and the Internet of Things (IoT). This surge presents a lucrative opportunity for beginners looking to dive into the circuit board manufacturing industry, which is often considered a pivotal foundation for various technological innovations.

Starting a venture in circuit board manufacturing requires a comprehensive understanding of both the technical aspects and market dynamics. New entrants must familiarize themselves with critical processes such as design, prototyping, and assembly, as well as the regulatory standards that govern quality and safety in manufacturing. Reports indicate that companies that invest in automated systems and sustainable practices can achieve significant competitive advantages, optimizing production efficiency and reducing waste.

As the demand for sophisticated electronic solutions continues to escalate, aspiring manufacturers must harness the latest advancements in materials and technology to remain relevant in the market. By strategically positioning themselves within this thriving sector and leveraging data-driven insights, newcomers can establish a foothold in the world of circuit board manufacturing, contributing to the evolution of the electronics landscape in the coming years.

Understanding the basics of circuit board manufacturing is crucial for beginners looking to enter this field. The manufacturing process typically begins with designing the circuit. Utilizing software tools for computer-aided design (CAD), beginners will outline the layout of the circuit board, including the placement of components and the routing of electrical pathways. This foundational step is essential as it determines the board's performance and functionality.

Once the design is complete, the next phase involves the actual production of the circuit board. This includes several key steps such as printing the design onto a copper-clad laminate, etching to remove excess copper, and applying a solder mask to protect the conductive pathways. Knowledge about different materials, such as FR-4 and polyimide, is important, as it affects the board's durability and electrical properties. Beginners should also familiarize themselves with assembly techniques, including how to solder components accurately to ensure reliable connections. Through this understanding, aspiring manufacturers can effectively navigate the complexities of circuit board production.

This bar chart illustrates the estimated manufacturing costs for various types of circuit boards in 2025. Each type presents a different cost per square foot, which is crucial for beginners to understand when starting circuit board manufacturing.

Starting a circuit board manufacturing venture requires a firm grasp of essential tools and equipment that are crucial for efficient production processes. In 2025, the global printed circuit board (PCB) market is projected to reach over $80 billion, reflecting a robust demand for electronic components across various industries, including automotive, telecommunications, and consumer electronics. To capitalize on this growth, beginners must invest in fundamental tools that facilitate both prototyping and mass production.

The cornerstone of any circuit board manufacturing setup is the PCB design software, which allows users to create and modify layouts. Advanced tools like CAD (Computer-Aided Design) software enable precise component placement and circuit tracing, ensuring optimized performance. Following design, the production process necessitates equipment such as CNC routers for cutting and milling, pick-and-place machines for assembling components, and reflow ovens for soldering connections. According to a 2023 industry report, companies utilizing automated assembly lines report up to 40% reductions in production time, showcasing the importance of modern machinery in increasing efficiency.

Moreover, quality control instruments, including oscilloscopes and multimeters, are vital for testing and validating the functionality of circuit boards. A reliable testing protocol can reduce defect rates and enhance customer satisfaction. As industries shift towards more complex electronic applications, the demand for high-quality, precision-engineered PCBs is surging, making the acquisition of these essential tools a critical step for any aspiring manufacturer in the electronic components landscape.

| Tool/Equipment | Description | Purpose | Estimated Cost ($) |

|---|---|---|---|

| CAD Software | Computer-aided design tools for circuit design | Design circuit layouts | 500 - 2000 |

| Etching Tank | A tank for chemical etching of copper | Remove unwanted copper from PCBs | 300 - 800 |

| Drilling Machine | Automated machine for drilling holes in PCBs | Create holes for components | 1000 - 5000 |

| Soldering Station | Station for soldering components onto PCBs | Assemble electronic components | 200 - 1000 |

| Multimeter | Device for measuring electrical values | Test and troubleshoot circuits | 50 - 300 |

| Pick and Place Machine | Machine for placing components on PCBs | Automate PCB assembly | 5000 - 20000 |

| PCB Laminator | Machine for laminating PCB layers | Combine layers of PCBs | 2000 - 8000 |

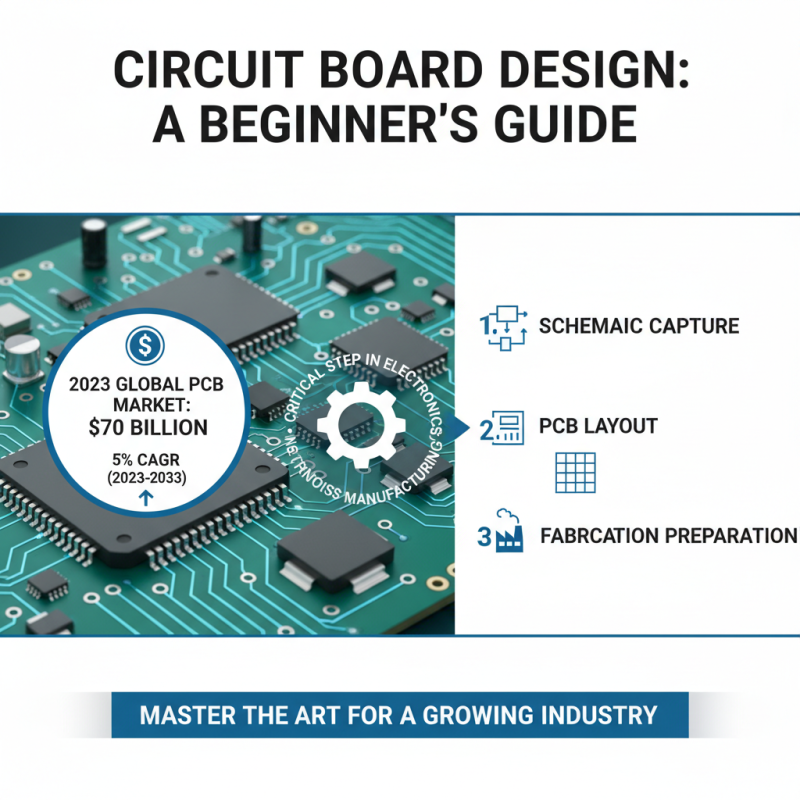

Designing a circuit board is a critical step in the manufacturing process for beginners venturing into the electronics industry. As of 2023, the global printed circuit board (PCB) market was valued at approximately $70 billion, with an expected compound annual growth rate (CAGR) of around 5% over the next decade (Industry Research Reports). This growth signifies an increasingly competitive landscape, making it essential for newcomers to master the art of circuit board design.

To begin with, aspiring designers should familiarize themselves with the various elements of PCB design software, such as schematic capture and layout tools. The first step involves creating a schematic diagram, which serves as a blueprint for the circuit. According to PCB design methodology, a clear understanding of electrical components and their connections is paramount. Reports indicate that the average time to design a PCB schematic can range from a few days to several weeks, heavily influenced by the complexity of the project and the designer's experience level.

Once the schematic is complete, the next phase is the layout process. During this stage, designers must carefully position components on the board and route the connections, taking into account factors like signal integrity and thermal management. Industry data shows that optimizing the layout can reduce manufacturing defects by up to 30%, underscoring the importance of meticulous design practice. By adhering to best practices and leveraging simulation tools, beginners can significantly enhance their PCB designs, contributing to higher quality and reliability in their manufacturing endeavors.

Choosing the right materials and components is critical for beginners venturing into circuit board manufacturing in 2025. The growing demand for advanced electronics has led to significant innovations in materials. According to a recent report by the Electronics Association, the global market for printed circuit boards is projected to reach $70 billion by 2025, highlighting the importance of selecting high-quality materials for competitiveness.

When selecting substrates, epoxy laminates are commonly favored for their excellent electrical insulation and thermal stability. Additionally, understanding the requirements for conductive materials, such as copper thickness and plating, is essential, as they directly affect the board's performance and durability. Moreover, sourcing components like resistors, capacitors, and integrated circuits requires a keen consideration of their specifications, reliability, and compatibility with your design.

Tips: Always choose materials that comply with industry standards such as IPC-6012 for multilayer boards. Regularly consult updated material datasheets for certifications and performance metrics, as these can greatly impact the longevity and efficiency of your circuit boards. Lastly, networking with local suppliers can provide insights into material trends and availability, ensuring your manufacturing process remains streamlined and cost-effective.

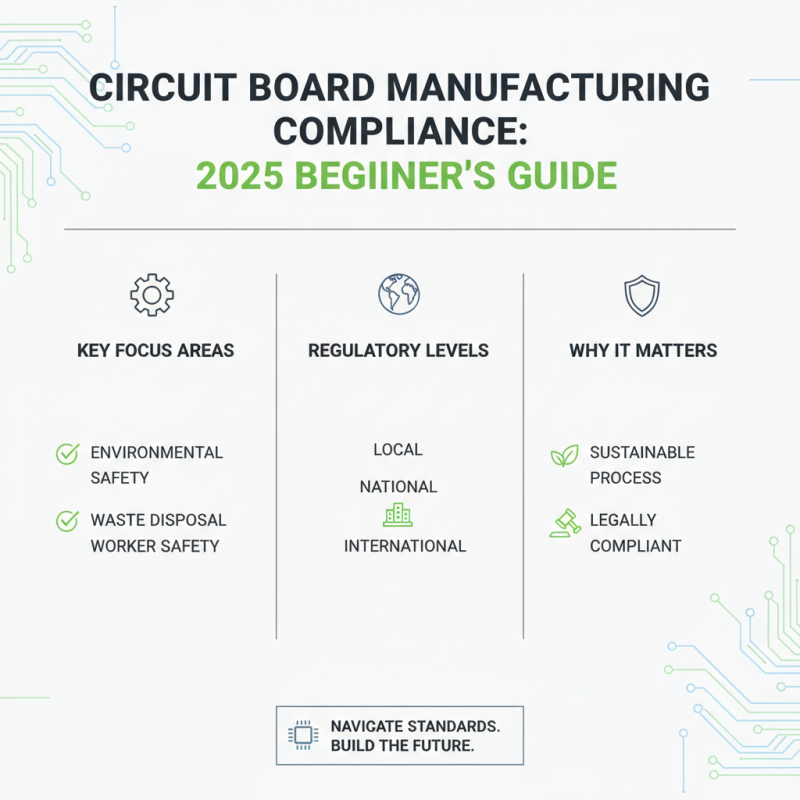

Navigating regulations and compliance in circuit board manufacturing is crucial for beginners entering the industry in 2025. As the technological landscape evolves, so do the standards that govern circuit board production. Manufacturers must familiarize themselves with local, national, and international regulations that pertain to environmental safety, waste disposal, and worker safety. Understanding these regulations can seem daunting, but it's essential for creating a sustainable and legally compliant manufacturing process.

One of the primary steps in ensuring compliance is obtaining the necessary certifications and permits before beginning production. This may include environmental assessments to determine the impact of operations and adherence to safety protocols. Engaging with industry groups and attending workshops can provide valuable insights into the latest regulatory changes. Moreover, implementing a quality management system can help track compliance and ensure that all aspects of manufacturing meet established standards. By prioritizing regulatory compliance from the outset, new manufacturers can avoid potential fines and disruption, thereby laying a solid foundation for their circuit board production business.