Our Commitment to a Greener Future

Circuit board assembly is a crucial process in the electronics industry. According to a recent market report, the global PCB market is anticipated to grow significantly, reaching an estimated value of $100 billion by 2027. This growth emphasizes the importance of circuit board assembly, as it is the backbone of modern electronics.

Every electronic device relies on a well-assembled circuit board. Poor assembly can lead to malfunctions, increased costs, and safety hazards. In fact, studies indicate that approximately 30% of industry failures are linked to assembly errors. Thus, effective circuit board assembly directly impacts product reliability and performance.

Moreover, companies must continuously adapt to evolving technology. Embracing advanced techniques is essential for staying competitive. However, not all manufacturers successfully achieve high assembly quality. Reflecting on these challenges can lead to improvements. In conclusion, circuit board assembly is not just a technical necessity; it is a pivotal factor in the success of electronic products.

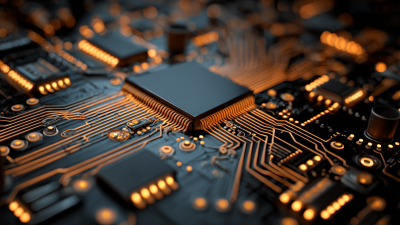

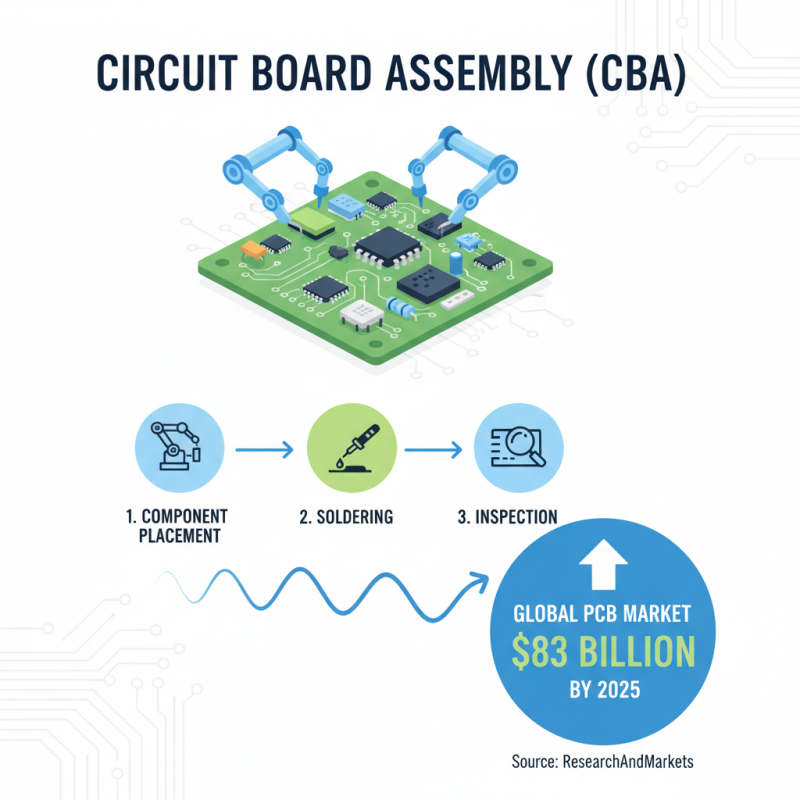

Circuit board assembly (CBA) is a vital process in the electronics industry. It involves the integration of various electronic components onto a printed circuit board (PCB). The assembly process typically includes component placement, soldering, and inspection. According to a report by ResearchAndMarkets, the global PCB market is projected to reach $83 billion by 2025. This highlights the growing significance of efficient circuit board assembly in meeting rising demand.

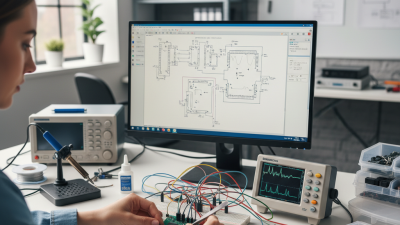

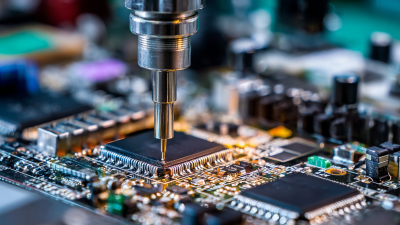

During the assembly process, precision is critical. Components must be correctly oriented and soldered without defects. A small error can lead to significant failures. The importance of quality control in PCB assembly cannot be overstated. Inadequate inspections can result in costly reworks or product recalls. Industry reports indicate that approximately 60% of electronic failures are linked to assembly defects. This statistic emphasizes the necessity for meticulous attention to detail.

Moreover, sustainable practices are increasingly relevant in circuit board assembly. Many companies now strive to reduce waste and energy consumption during production. However, achieving sustainability in CBA is challenging. The balance between efficiency and eco-friendly practices often needs more consideration. While automation improves speed, it can also lead to oversights if not managed judently. The path forward requires ongoing reflection and adaptation in the assembly process.

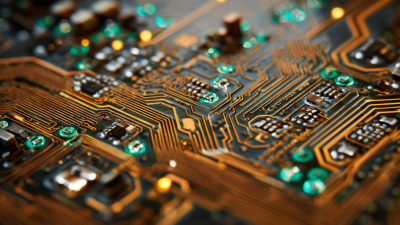

Circuit board assembly (CBA) is a critical process in electronics, involving various key components. These components include the circuit board itself, solder, and electronic parts like resistors and capacitors. Each plays an essential role. For instance, the circuit board acts as a foundation. It connects various components and facilitates communication.

Materials used in CBA influence both the performance and reliability of the final product. The most common material for circuit boards is FR-4, a glass-reinforced epoxy laminate. This material accounts for about 70% of the market due to its excellent electrical insulation. However, its environmental impact raises concerns. Alternatives like biodegradable substrates are gaining attention.

Solder is another vital element. It joins components to the circuit board. Lead-free solder is increasingly preferred due to health regulations. However, the transition from traditional solder has caused challenges. Some manufacturers report issues with reliability and performance consistency. As the industry evolves, understanding these materials and their functions is crucial for improving assembly quality.

| Component | Material | Function |

|---|---|---|

| Printed Circuit Board (PCB) | Fiberglass, Copper | To provide a platform for connecting electronic components |

| Solder | Tin-Lead Alloy or Lead-Free Alloy | To join electronic components to the PCB |

| Resistors | Carbon Film, Metal Film | To control the flow of electric current |

| Capacitors | Ceramic, Electrolytic | To store electrical energy temporarily |

| Integrated Circuits (ICs) | Silicon | To perform various electronic functions in a compact form |

| Diodes | Silicon | To allow current to flow in one direction only |

| Transistors | Silicon, Gallium Arsenide | To amplify or switch electronic signals |

Circuit Board Assembly (CBA) plays a critical role in the performance and reliability of electronic devices. Every electronic component needs a stable platform to function effectively. Circuit boards provide that base. They connect various parts, allowing signals to travel seamlessly. When assembled correctly, they enhance device efficiency. Yet, mistakes in CBA can lead to costly failures.

The materials used in circuit board assembly significantly influence device performance. For instance, high-quality substrates can improve signal integrity and durability. However, lower quality options may cause overheating or signal loss. Designers often wrestle with choices between cost and quality. Sometimes, shortcuts are taken, leading to future reliability issues.

Even the layout of components matters deeply. A well-thought-out design can reduce electromagnetic interference. However, poor spacing may create unwanted noise or signal degradation. Engineers often reflect on their strategies to ensure optimal designs. Continuous improvement becomes essential in achieving robust and efficient electronic devices.

This chart illustrates the significance of various factors contributing to the performance and reliability of electronic devices in relation to Circuit Board Assembly (CBA). The data includes the percentage impact of the assembly process on device longevity, performance, and failure rate.

The global circuit board assembly market has been experiencing remarkable growth. According to industry reports, the market size is projected to reach $83 billion by 2025. This growth is driven by the rising demand for electronic devices. The proliferation of smart technology and IoT devices plays a significant role in this trend.

Statistics reveal that Asia-Pacific dominates the circuit board assembly market. In fact, this region accounted for over 45% of the global market share in 2022. This reflects the concentration of manufacturing in countries like China, Japan, and South Korea. Many companies are investing heavily in automation and advanced technologies to enhance efficiency and reduce costs. This is a critical factor for maintaining competitiveness.

Tips: Always consider the quality of materials used in circuit board assembly. It can greatly affect the longevity of your products. Regular audits of assembly processes are essential. Small mistakes can lead to significant issues, impacting overall production. Keep an eye on industry trends; they can provide valuable insights. The rapid evolution of technology means companies must stay adaptive.

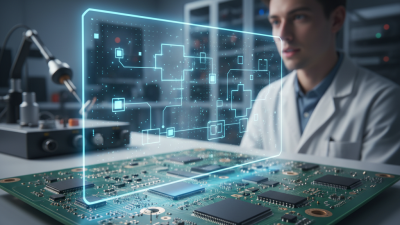

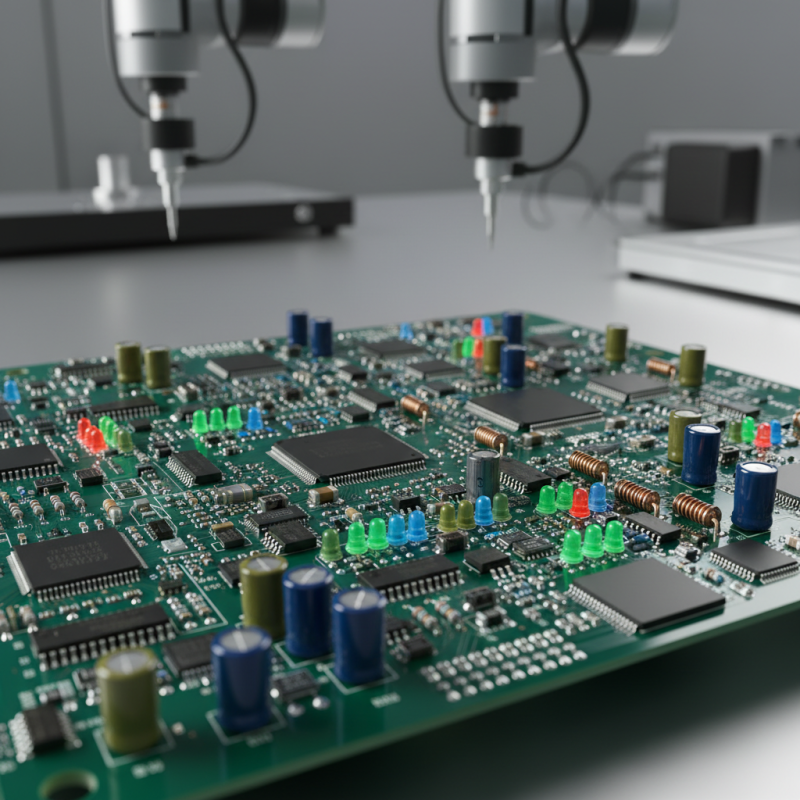

The future of circuit board assembly technology is bright, filled with potential and challenges. Automation is a key player in this evolution. Advanced robotic arms are increasingly used for precision tasks. They can place components more accurately and quickly than humans can. However, the initial investment in automation can be prohibitive for smaller companies.

Another trend is the shift towards eco-friendly materials. Sustainable circuit boards use biodegradable options and reduce electronic waste. This move is crucial as environmental awareness grows. Yet, the transition involves complex regulatory challenges. Not all manufacturers are equipped to handle these changes, which can create a divide in the industry.

Moreover, the integration of artificial intelligence in assembly processes is noteworthy. AI can predict failures and optimize production lines. This innovation promises to enhance efficiency. But reliance on AI raises questions about job security in the workforce. As we advance, we must balance technological progress with human concerns. It's a complex landscape that requires thoughtful navigation for sustainable growth.