Our Commitment to a Greener Future

Effective PCB design is vital in today’s technology-driven world. According to a survey by IPC, 70% of engineers believe that PCB design quality directly influences product reliability. This statistic highlights the importance of mastering the art of “design PCB.” Industry expert Dr. Jane Smith emphasizes, “Precision in PCB design can reduce production costs and enhance device performance.”

Many designers overlook essential factors such as component placement and thermal management. Neglecting these aspects can lead to significant inefficiencies and product failures. For instance, improper layout may cause signal interference, impacting overall functionality. Understanding these nuances is crucial for successful design.

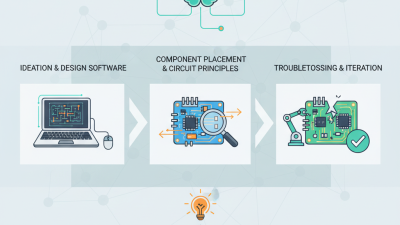

Additionally, proper tooling and software are imperative. However, many designers don’t utilize the latest solutions available in the market. A failure to adopt innovative design strategies can yield outdated products that do not meet current market demands. Thus, reflecting on one's design process is essential for achieving excellence in PCB design.

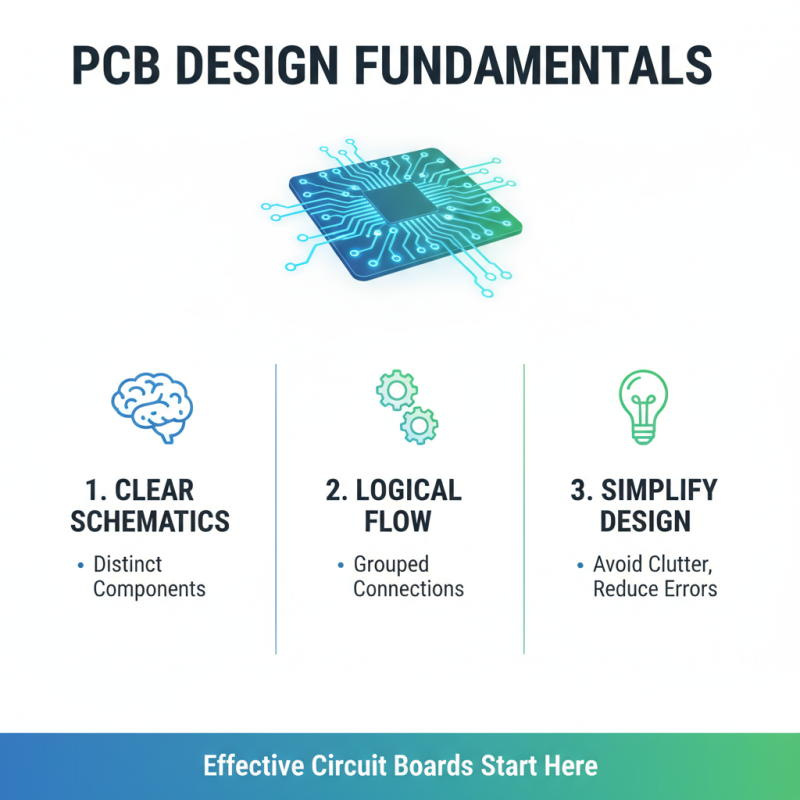

Understanding the fundamentals of PCB design is crucial for creating effective circuit boards. Begin with clarity in the schematic. Each component should be distinctly marked. A cluttered schematic can easily lead to errors. Ensure you have a logical flow and grouping of connections. Simplicity often trumps complexity in design clarity.

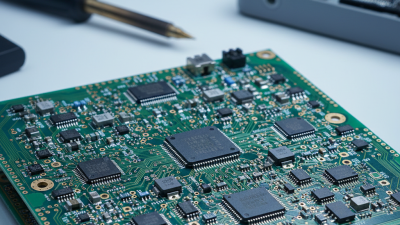

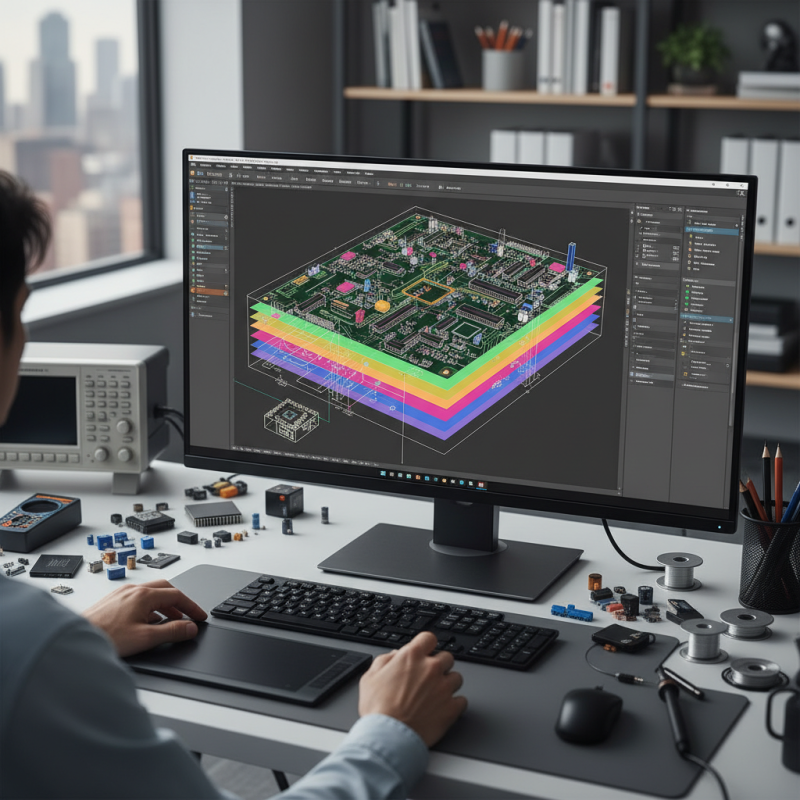

Layout matters significantly. A good layout optimizes space and minimizes interference. Components should be placed logically, considering signal flow. However, many designers overlook this and end up with chaotic placements. Utilize layers wisely, but don't complicate your structure. Layer management can become a nightmare if not organized properly. Pay attention to trace widths and spacing as they impact performance.

Moreover, testing your design is not just an afterthought. It should be integrated into your process. Many encounter unforeseen issues only during final testing, leading to revisions. Simulate designs before committing to a prototype. Mistakes during the design phase can cascade into larger problems. Take the time to reflect on past designs. Learning from mistakes can lead to more refined and successful PCB designs in the future.

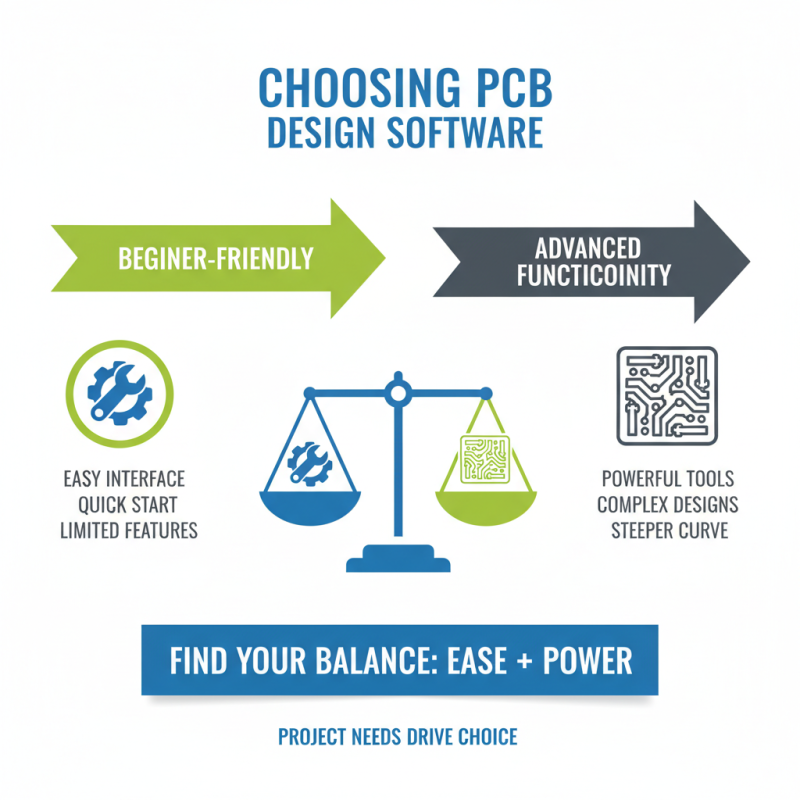

When choosing PCB design software, consider your project needs carefully. Some tools are user-friendly, perfect for beginners. However, they may lack advanced features. A simpler interface can be appealing, but it might limit your design capabilities. Look for software that offers a balance of ease and functionality.

Advanced users often seek software with strong simulation features. These can help predict performance issues before manufacturing. But be cautious. Sometimes, complex tools can be overwhelming. They may introduce a steep learning curve, leading to frustration. Select software that offers tutorials or a supportive community. This can ease the transition.

Ultimately, the right software should align with your goals. Think about the type of projects you undertake. If you frequently work on intricate designs, investing time in learning robust software may pay off. Don’t hesitate to explore several options before making a decision. Each choice comes with its unique strengths and weaknesses. Finding the perfect fit requires experimentation.

When designing PCBs, layer stack-up is crucial. It determines the performance and integrity of your circuit. A good stack-up minimizes electromagnetic interference. Consider using a ground plane. It helps reduce noise and improves signal quality. Proper grounding is often overlooked but essential for stability.

Routing is another vital aspect. An effective routing strategy enhances signal integrity. Maintain short traces to minimize resistance. Use wider traces for high current paths. This reduces heat and improves reliability.

Remember to avoid tight angles in your routing. Sharp turns can lead to impedance issues. Always aim for gradual curves. It may seem small, but these details matter. Investing time in thoughtful design will pay off in the end.

When designing printed circuit boards (PCBs), component placement and sizing are critical for performance. Research shows that improper placement can lead to signal integrity issues. According to a report by IPC, nearly 50% of PCB failures are due to design errors. This highlights the need to prioritize placement.

Arrange components logically. Place high-frequency parts close to the edge of the board. This minimizes trace lengths and reduces noise. Create a clear flow for power and ground connections. Keeping these areas tidy is key. Data suggests that optimal component spacing can improve thermal performance by up to 30%.

Consider component size carefully. Larger components may require more space for heat dissipation. However, overcrowding can lead to excess heat, causing failures. Some designs still overlook this, risking reliability. Using thermal simulation software helps in refining these decisions. Balancing component sizing with placement can enhance both functionality and reliability. Aim for clarity and efficiency in your designs.

Testing and validation play a crucial role in PCB design. They ensure that the final product performs as expected. Inadequate testing can lead to failures in critical applications. A small oversight during the design phase can result in significant issues later. For instance, issues like short circuits or signal integrity problems can emerge. Without thorough validation, these problems can remain unnoticed until it’s too late.

Implementing a robust testing process is essential. This includes functional tests, mechanical tests, and environmental tests. Designers often assume their designs will work seamlessly. However, this belief can lead to complacency. Running tests can highlight areas needing improvement, such as layout errors or component selection issues. By incorporating feedback from testing, designers can refine their products. Regularly reviewing these tests can create better designs in future projects, helping to ensure reliability and performance. Learning from mistakes is a part of the process, and reflection is vital for growth.