Our Commitment to a Greener Future

The growing demand for electronics is reshaping the landscape of manufacturing. Printed circuit board assembly (PCBA) plays a critical role in this evolution. According to a recent report by MarketsandMarkets, the global PCBA market is expected to reach $25 billion by 2025. This places greater emphasis on the quality and efficiency of assembly processes.

Experts like Dr. Alice Chan, a leading authority in electronic manufacturing, emphasize the importance of PCBA. She states, "Effective printed circuit board assembly is the backbone of reliable electronic devices." Her insights highlight how vital it is for manufacturers to invest in advanced techniques and quality controls.

However, challenges remain. Manufacturers struggle with issues such as supply chain disruptions and the need for skilled labor. These factors can hinder the benefits of PCBA. Striking a balance between innovation and practicality in PCB assembly requires constant reflection. The future of electronics depends on optimizing these processes for improved performance and reliability.

Understanding Printed Circuit Board Assembly in Electronics Manufacturing

Printed Circuit Board Assembly (PCBA) plays a critical role in modern electronics manufacturing. It integrates various electronic components onto a single board, ensuring efficient functionality. According to a recent report by Mordor Intelligence, the global PCB market is projected to reach $90 billion by 2025, reflecting the growing importance of PCBA in the industry. This process not only improves assembly speed but also enhances reliability when done correctly.

Many manufacturers consider materials used in PCBA as crucial. Poor choices can lead to defects and increased costs. A DfR Solutions study highlights that approximately 30% of electronic failures stem from PCB-related issues. It’s vital to choose high-quality materials to optimize performance.

Tips: Always conduct a thorough design review. Involve your engineering team early to catch potential issues. Testing prototypes before full-scale production is essential. Fabrication mistakes are costly and might delay manufacturing. Engaging with experienced PCB fabricators can mitigate risks significantly. The industry's future relies on ongoing innovation and adaptability. Regularly reassess your production practices to stay competitive.

| Benefit | Description | Impact |

|---|---|---|

| Cost Efficiency | Reduces manufacturing costs by streamlining processes. | Lower production costs lead to higher profit margins. |

| Speed of Production | Faster assembly processes using automated equipment. | Quicker time to market for electronic products. |

| Design Flexibility | Allows for complex designs and modifications as needed. | Innovative products that can adapt to market changes. |

| Quality Assurance | Ensures high-quality standards through rigorous testing. | Reduced defects and warranty claims. |

| Scalability | Easily scalable operations to meet increasing demand. | Ability to grow without compromising quality. |

| Technical Expertise | Access to experts in PCB design and manufacturing. | Enhanced product performance and reliability. |

| Material Selection | Use of high-quality materials for durability. | Longer lifespan and better performance of assemblies. |

| Environmental Challenge | Minimizes waste through efficient production methods. | Positive environmental impact and cost savings. |

| Supply Chain Integration | Enhances collaboration with suppliers for components. | Streamlined processes and reduced lead times. |

| Innovation and R&D | Supports research and development for new technology. | Fosters continuous improvement and product advancement. |

The assembly of printed circuit boards (PCB) plays a crucial role in electronics manufacturing. By improving production efficiency, PCB assembly techniques can significantly reduce costs and lead times. These benefits are vital in today’s fast-paced market. Streamlining processes can help manufacturers stay competitive and responsive.

One critical tip is to implement automation where possible. Automated setups for soldering and testing can enhance precision. However, not every process may be suitable for automation. Regular evaluations of techniques can identify areas needing improvement. Manual assembly still holds value, especially for complex designs.

Another tip is to focus on quality control throughout the assembly process. Continuous monitoring can minimize defects and enhance reliability. A robust quality process may seem time-consuming upfront, but it often pays off in the long run. Regular audits help capture areas that are underperforming. Adjustments based on feedback lead to more efficient practices.

Emphasizing communication among team members is essential. Clear instructions reduce misunderstandings and mistakes. Yet, it's important to remain flexible. The assembly process can vary from batch to batch, and adapting proactively is crucial. This kind of agility contributes to an efficient PCB assembly, paving the way for innovation.

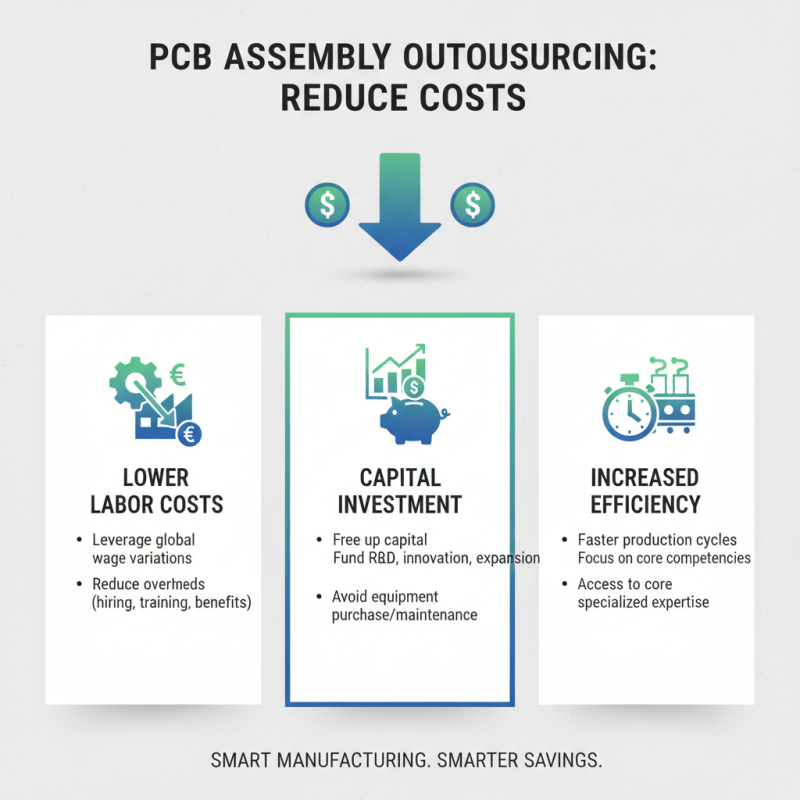

Outsourcing printed circuit board (PCB) assembly can lead to significant cost reductions for electronics manufacturers. Many companies struggle with the expenses related to in-house production. Labor costs can be high, especially in regions with elevated wage levels. By outsourcing, businesses can take advantage of lower labor costs in other areas. This can free up capital for investment in other critical projects.

Moreover, outsourcing reduces overhead costs. Companies no longer need to maintain expensive facilities or invest in specialized machinery. They can partner with expert firms that already have the necessary equipment and workforce. This arrangement often leads to faster production times. However, reliance on external partners can be risky. Poor communication may lead to mistakes and delays, affecting product timelines.

Another benefit lies in scalability. Outsourced assembly can adapt quickly to shifting demands. This means companies can manage inventory more efficiently, avoiding excess production or shortages. Yet, it's crucial to vet partners thoroughly. Not every outsourcing company offers the same level of quality. Poor choices can impact the product’s final performance and reliability. Finding a trustworthy partner requires careful consideration and sometimes trial and error.

Quality assurance in printed circuit board (PCB) assembly is a critical aspect of electronics manufacturing. High-quality PCBs lead to better performance and increased product reliability. According to industry reports, around 30% of electronic failures occur due to faulty PCBs. Implementing robust testing protocols can significantly reduce this risk.

Testing methods like Automated Optical Inspection (AOI) and X-ray inspection provide crucial feedback during the assembly process. AOI detects defects on the surface, identifying misalignments and soldering issues early. X-ray inspection finds hidden defects in solder joints of multi-layer boards. A study showed that regular testing can improve product yields by up to 70%.

Quality assurance also impacts long-term costs. Poorly assembled PCBs can lead to higher failure rates, resulting in costly recalls and repairs. In fact, a report revealed that the average cost of a faulty PCB can reach over $1 million when considering production losses and reputation damage. Therefore, investing in thorough testing not only enhances quality but also protects future revenue.

The role of PCB assembly in electronics manufacturing is vital for advancing technology. According to industry reports, the global PCB market is expected to reach $80 billion by 2026. This growth signifies the increasing demand for innovative electronics. PCB assembly supports this demand by providing reliable connections in compact designs.

Printed circuit boards enable complex circuits to fit into smaller devices. This flexibility is critical for smartphones, wearables, and IoT devices. A recent study highlighted that about 30% of engineers struggle with thermal management in compact PCB designs. It’s a challenge that needs mindful strategies and attention. Many manufacturers overlook testing at this stage, which can lead to device failures.

Moreover, sustainability is becoming a pressing issue in PCB assembly. Reports indicate that more than 80% of electronic waste comes from discarded devices. Addressing this problem requires sustainable practices in design and material sourcing. Yet, many companies still focus on cost over environmental impact. Balancing innovation with sustainability remains a complex issue for the industry.